Single Acting Cylinder Construction Working Application Types

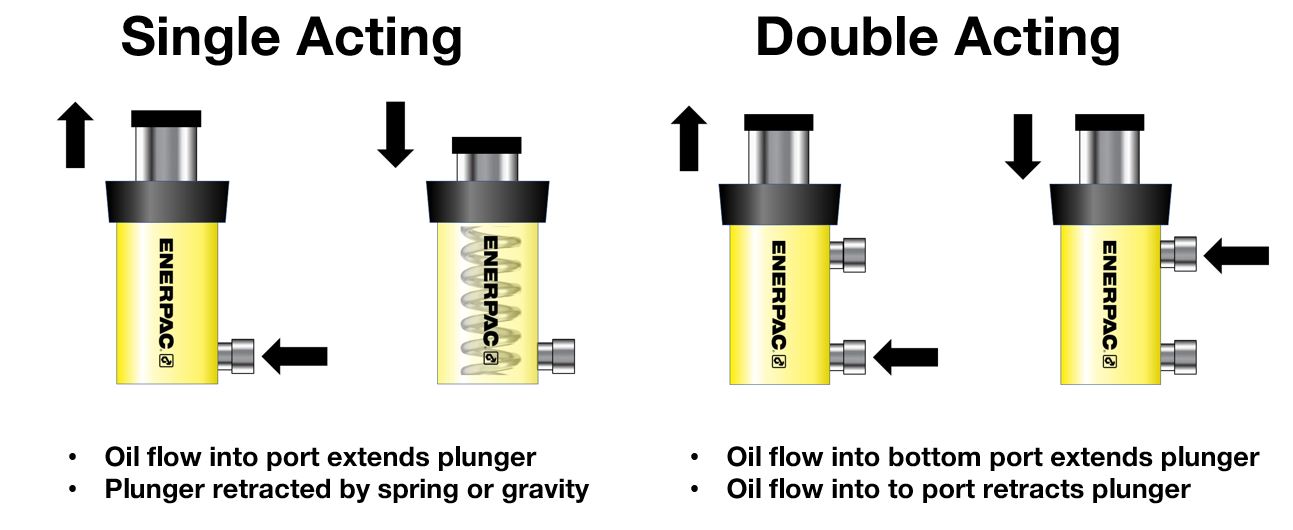

Single Acting Vs Double Acting Hydraulic Cylinders Enerpac Blog In this video, i explained single acting cylinder (linear actuators)construction of single acting cylinderworking of single acting cylinderapplication of sin. Single acting cylinders; double acting cylinders; single acting cylinders. single acting cylinders only apply compressed air to one side of the piston face, leaving the other side exposed to the atmosphere. only one direction of work can be produced by the cylinder. a built in spring controls the piston’s return movement.

Pneumatic Cylinder Principles Types Application 45 Off Single acting cylinders depending on whether it is routed to the cap end or rod end, the pressurized fluid may extend or retract the cylinder, respectively. in either case, the force generated by gravity or a spring returns the piston rod to its original state. single acting cylinder (spring return type) – single acting cylinders can be. How single acting hydraulic cylinders work. the simpler design of a single acting hydraulic cylinder creates fewer components to maintain. for equipment and projects needing an effective and reliable hydraulic cylinder, single acting may be your best option. single acting cylinders have only one acting port that allows the hydraulic fluid to enter. Figure 1: single acting hydraulic cylinder. advantages of spring return single acting hydraulic cylinder. the cost of these cylinders is less. damage due to electric power outage can be avoided. disadvantages of spring return single acting hydraulic cylinder. it is suitable oniy for low pressure operations. Single acting cylinder. only one side of the piston is supplied with certain working pressure. force acts in one direction to control the movement, returns to normal state by an external force such as a spring inside. types of single acting cylinders. based on the operation the single acting cylinders are classified as.

Single Vs Double Acting Cylinder Figure 1: single acting hydraulic cylinder. advantages of spring return single acting hydraulic cylinder. the cost of these cylinders is less. damage due to electric power outage can be avoided. disadvantages of spring return single acting hydraulic cylinder. it is suitable oniy for low pressure operations. Single acting cylinder. only one side of the piston is supplied with certain working pressure. force acts in one direction to control the movement, returns to normal state by an external force such as a spring inside. types of single acting cylinders. based on the operation the single acting cylinders are classified as. Single acting air cylinders work by using air pressure on one side of a piston to move it. once the air pressure is gone, a spring inside the cylinder pushes the piston back to where it started. this design is simple but effective, relying on both air pressure and a spring to function. the piston seals are crucial. Single acting vs. double acting pneumatic cylinder. the difference between single acting and double acting pneumatic cylinders exists in their design or construction, working principle, and application specifics. construction. the one way barrel has a single opening for compressed air, which works as an inlet as the exhaust port.

Comments are closed.