Single Acting Vs Double Acting Pneumatic Cylinder Tameson

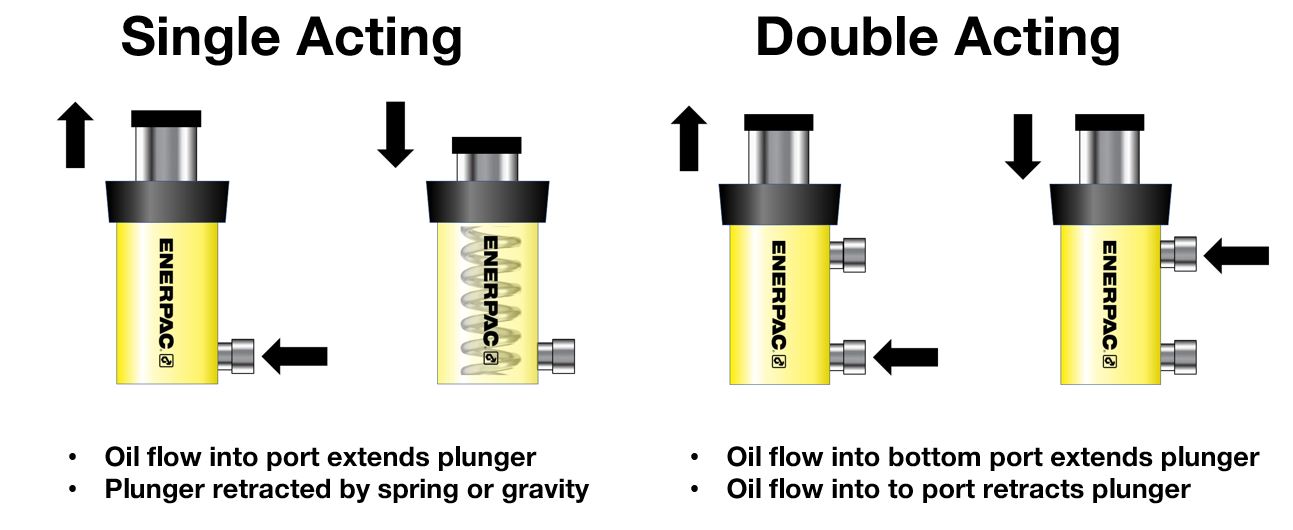

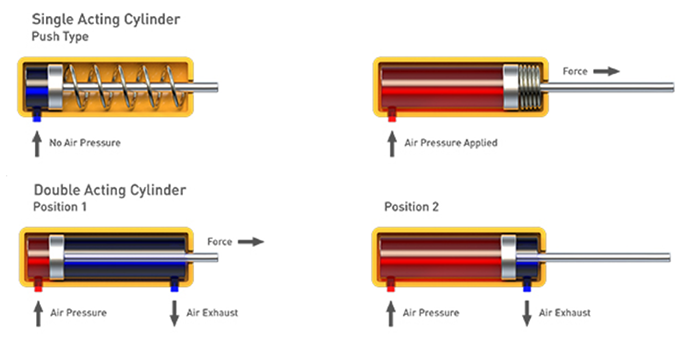

Single Acting Vs Double Acting Hydraulic Cylinders Enerpac Blog Single acting pneumatic cylinders have the following advantages and disadvantages: cost: single acting cylinders are the cost effective solution for applications that only require one direction of movement. air pressure: these cylinders require less air pressure than double acting pneumatic cylinders. fail safe: if air pressure is lost due to a. A short description is below, but see our single acting vs double acting pneumatic cylinder article to learn more. single acting pneumatic cylinder. a single acting pneumatic cylinder uses compressed air to drive the piston in only one direction. a mechanical spring moves the piston to its original position. figure 3 shows the two design.

How Can You Achieve Cylinder Flow Reduction Double acting cylinders use compressed air to extend and retract the piston rod. read our article on single acting vs double acting pneumatic cylinders for more information on the features of each type. 3. force and bore size. a pneumatic cylinder must produce enough force to move the load. use the formula f = m × a to calculate the force. As a result, they offer varied benefits and suit different automation tasks. a single action type is less precise but inexpensive and more economical to operate. the dual motion style has more control but costs more. this article explains the difference between single acting and double acting pneumatic cylinder types, including their specific. As a pneumatic actuator, a double acting pneumatic cylinder relies on compressed air to generate bidirectional force. whether extending or retracting, pneumatic cylinders convert energy found in compressed air into linear motion. note that single acting cylinders will exert force in only one direction, specifically extension. A single acting pneumatic cylinder is a cylinder where the thrust or output force is developed in only one direction. the piston is returned by a fitted spring, or by some other external means such as a weight, mechanical movement, gravity, or an external spring. they have a single port to allow compressed air to enter the cylinder to move the.

Comments are closed.