Single And Double Acting Hydraulic Cylinders

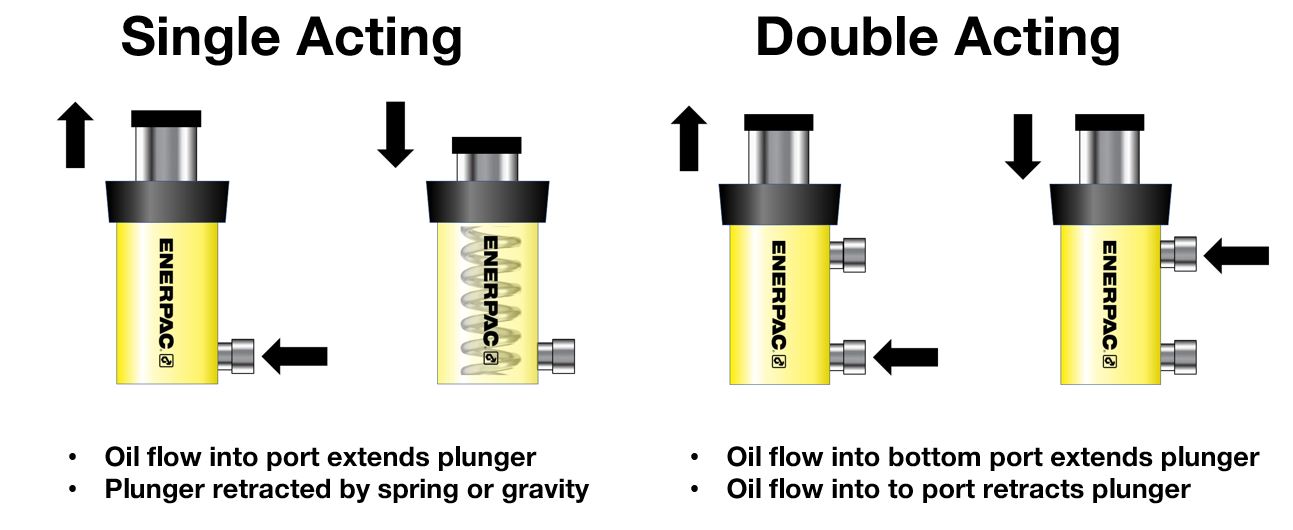

Single Acting Vs Double Acting Hydraulic Cylinders Enerpac Blog 0. when comparing single acting vs double acting hydraulic cylinders, the most visible difference is the number of couplers or connection ports. a single acting hydraulic cylinder includes just one port. this is where the hydraulic fluid enters and forces the plunger out in one direction. a double acting cylinder includes two ports. In this video, we will explain the difference between a single acting hydraulic cylinder and a double acting hydraulic cylinder. find out more at sar.

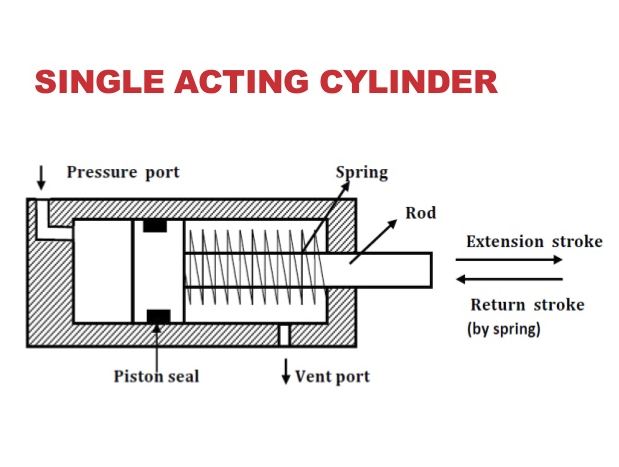

Single And Double Acting Hydraulic Cylinders Produced By Hydraulic Single acting. a single acting cylinder in a reciprocating engine is a cylinder in which the working fluid acts on one side of the piston only. a single acting cylinder relies on the load, springs, other cylinders, or the momentum of a flywheel, to push the piston back in the other direction. single acting cylinders are found in most kinds of. Comparison of single acting vs. double acting cylinders* in 70 words. single acting cylinders use hydraulic fluid to move the piston in one direction, with a spring or gravity returning it. they are simpler and cost effective but limited in functionality. double acting cylinders use hydraulic fluid for both extending and retracting the piston. Advantages of double acting cylinder. below are a few advantages of double acting cylinder: they use less energy while being faster and stronger. there is more movement control because the air moves two ways. they’re more likely to be iso compliant than single acting hydraulic cylinders. stroke and bore size variation. Available in several different body styles, including tie rod, welded and telescopic, hydraulic cylinders can be single acting or double acting. single acting cylinders vs double acting cylinders single acting cylinders. in a single acting hydraulic cylinder, piston force is applied in a single direction when pressurized oil extends the rod.

What Are Single Acting Double Acting Hydraulic Cylinders By Vcom Advantages of double acting cylinder. below are a few advantages of double acting cylinder: they use less energy while being faster and stronger. there is more movement control because the air moves two ways. they’re more likely to be iso compliant than single acting hydraulic cylinders. stroke and bore size variation. Available in several different body styles, including tie rod, welded and telescopic, hydraulic cylinders can be single acting or double acting. single acting cylinders vs double acting cylinders single acting cylinders. in a single acting hydraulic cylinder, piston force is applied in a single direction when pressurized oil extends the rod. Single acting cylinders have power up and gravity down capabilities, whereas double acting cylinders have power up and power down options. two directional power provides double acting cylinders more control and versatility. double acting cylinders offer more precise stroke movements and increased flexibility. Parker’s single acting telescopic (sat) hydraulic cylinders and double acting cylinders provide reliability and safety, efficient performance, increased operating pressure, and long service life. 2,000 psi rated.

Comments are closed.