Single And Double Acting Vs Single And Double Ended Cylinders ођ

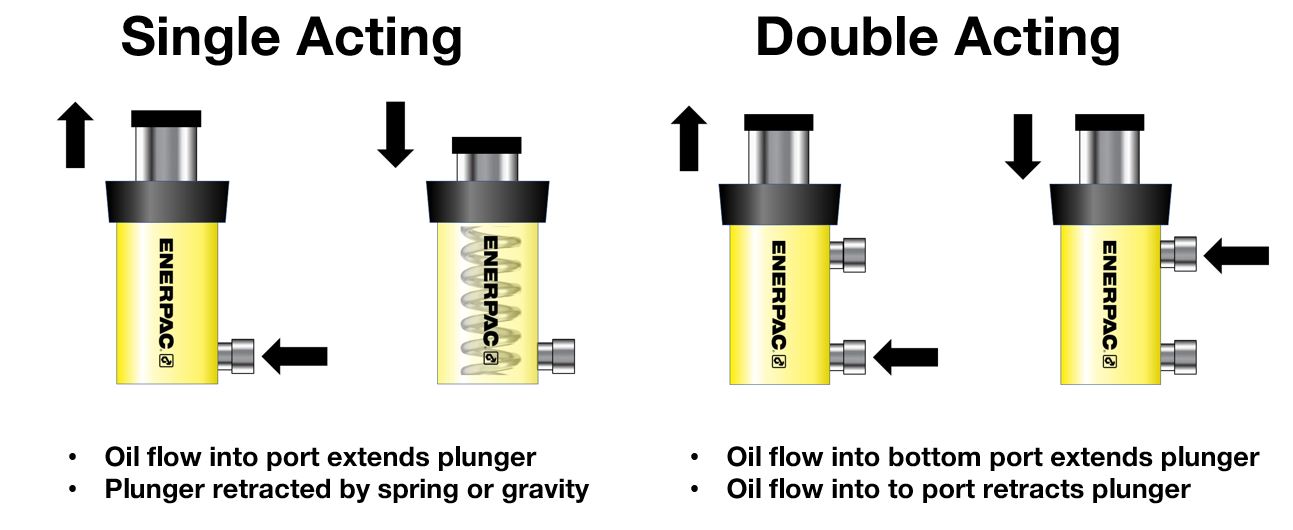

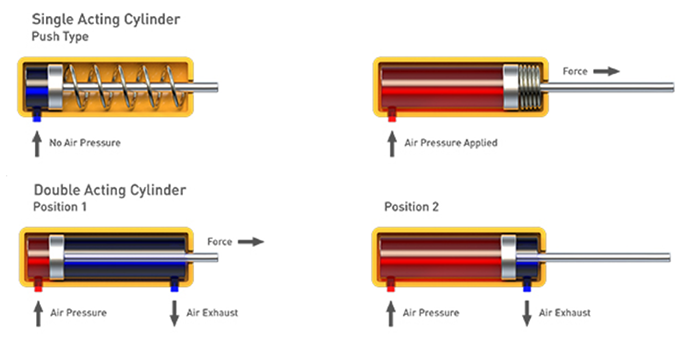

Single Acting Vs Double Acting Hydraulic Cylinders Enerpac Blog 0. when comparing single acting vs double acting hydraulic cylinders, the most visible difference is the number of couplers or connection ports. a single acting hydraulic cylinder includes just one port. this is where the hydraulic fluid enters and forces the plunger out in one direction. a double acting cylinder includes two ports. Single acting vs double acting cylinder: differences in work. when considering a single acting vs double acting cylinder, their function and purpose play the biggest role. the single acting cylinder function is simple, moving in one direction due to a force applied by compressed air or a plunger. it moves back using a spring or even just gravity.

How Can You Achieve Cylinder Flow Reduction Comparison of single acting vs. double acting cylinders* in 70 words. single acting cylinders use hydraulic fluid to move the piston in one direction, with a spring or gravity returning it. they are simpler and cost effective but limited in functionality. double acting cylinders use hydraulic fluid for both extending and retracting the piston. The additional components and complexity of double acting cylinders contribute to higher initial costs compared to single acting cylinders. this increased upfront investment may pose challenges for your projects with budget constraints or limited resources, requiring careful consideration of cost benefit analysis and long term value. A double acting cylinder uses hydraulic power to both extend and retract. you can tell if a cylinder is double acting by looking at the number of ports. see the image below as an example. in contrast, a single acting cylinder has an a port for running the piston down by pressure from the pump but is retracted with an internal spring. Hydraulic equipment and machines utilize single acting and double acting cylinders, and each type has its advantages. single acting cylinders are simpler and easier to maintain than double acting cylinders. however, with more fluid in the pressurized chamber, double acting actuators are easier for an operator to control.

Comments are closed.