Smart Sensing Hydraulic Cylinder Solutions Fluid Power Journal

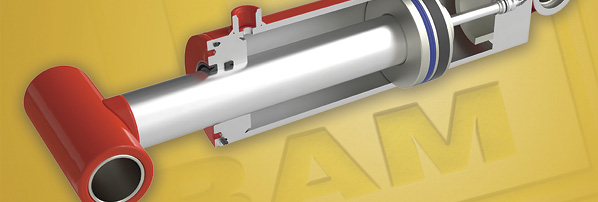

Smart Sensing Hydraulic Cylinder Solutions Fluid Power Journal Use ram smart sensing hydraulic cylinders on your equipment as a competitive advantage! contact our team of experts today for innovative solutions to all your hydraulic cylinder needs! ram industries inc. 877 799 1005. ramindustries . estimating@ramindustries . There are several other ways that position sensing can be done within the physical context of a hydraulic cylinder, including magnetoresistive sensing, resistive (potentiometric) sensing, hall effect sensing, and sensing using linear variable differential transformers (lvdts), but none come close to the volume of application of magnetostrictive.

Smart Sensing Hydraulic Cylinder Solutions Fluid Power Journal Parameters can be set digitally. with digital interfaces, hydraulic cylinders are now becoming the true “smart cylinders” and are one of the key building blocks when creating a smart hydraulics system. in this wind turbine rotor, hydraulic cylinders control the pitch of each blade individually. building block 3: smart fluid process sensing. The inductive proximity switch has a probe that inserts into your hydraulic cylinder’s head and or cap and fixes in place with a flange. o rings seal the sensor to prevent hydraulic oil from leaking out, and typically, two bolts to fasten the flange down. the probe must sit less than 2 mm or so away from the metal of the sensing target. Hydraulic fluid power systems are essential for a range of engineering applications such as transportation, heavy industry, and robotics. the scale of the industry is such that hydraulic pumps are estimated to account for 15% of all the energy consumption in the european union and yet the average efficiency of fluid power systems is only 22%. The new design involves a supporting cylinder with an integrated force measurement system in the piston rod: force is measured directly on the ball head. measurement signals are transmitted through the cylinder and end cap to the crane control system using a standard interface. consequently, sensitive cable connections outside the piston rod.

Fillable Online Smart Cylinder Solutions Fluid Power Journal Fax Hydraulic fluid power systems are essential for a range of engineering applications such as transportation, heavy industry, and robotics. the scale of the industry is such that hydraulic pumps are estimated to account for 15% of all the energy consumption in the european union and yet the average efficiency of fluid power systems is only 22%. The new design involves a supporting cylinder with an integrated force measurement system in the piston rod: force is measured directly on the ball head. measurement signals are transmitted through the cylinder and end cap to the crane control system using a standard interface. consequently, sensitive cable connections outside the piston rod. Position sensing hydraulic cylinders also improve productivity by allowing equipment operators to increase cycle speeds safely. precision and control: cranes and other load moving equipment require precise, controlled load holding and movement, especially in applications involving heavy loads. the instantaneous feedback provided by smart. By fluid power world editor | april 13, 2016 fill out the form below to watch this webinar on demand. in this video prince manufacturing will explain smart cylinders as to how they function, how to utilize the signal information, the benefits sensors provide and cost considerations critical to making the switch to position sensing cylinders.

Smart Sensing Hydraulic Cylinder Solutions Position sensing hydraulic cylinders also improve productivity by allowing equipment operators to increase cycle speeds safely. precision and control: cranes and other load moving equipment require precise, controlled load holding and movement, especially in applications involving heavy loads. the instantaneous feedback provided by smart. By fluid power world editor | april 13, 2016 fill out the form below to watch this webinar on demand. in this video prince manufacturing will explain smart cylinders as to how they function, how to utilize the signal information, the benefits sensors provide and cost considerations critical to making the switch to position sensing cylinders.

Comments are closed.