So Funktioniert Ein Zweileitungsverteiler What Really Happens Inside A Dual Line Distributor

So Funktioniert Ein Zweileitungsverteiler What Really Happens ођ Auf den ersten blick ist ein schmierstoffverteiler ein unscheinbarer metallblock mit leitungsanschlüssen auf allen seiten. erst der blick ins innere zeigt di. Auf den ersten blick ist ein schmierstoffverteiler ein unscheinbarer metallblock mit leitungsanschlüssen auf allen seiten. erst der blick ins innere zeigt di.

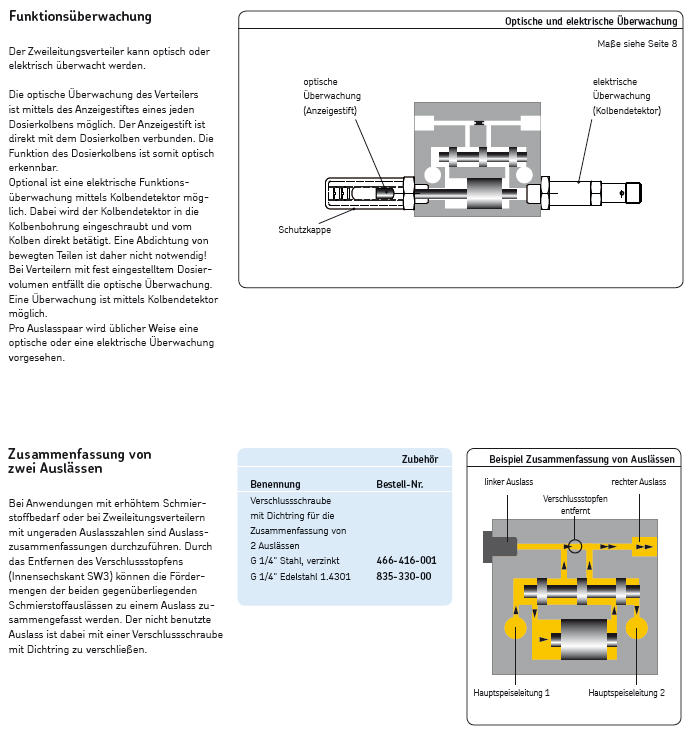

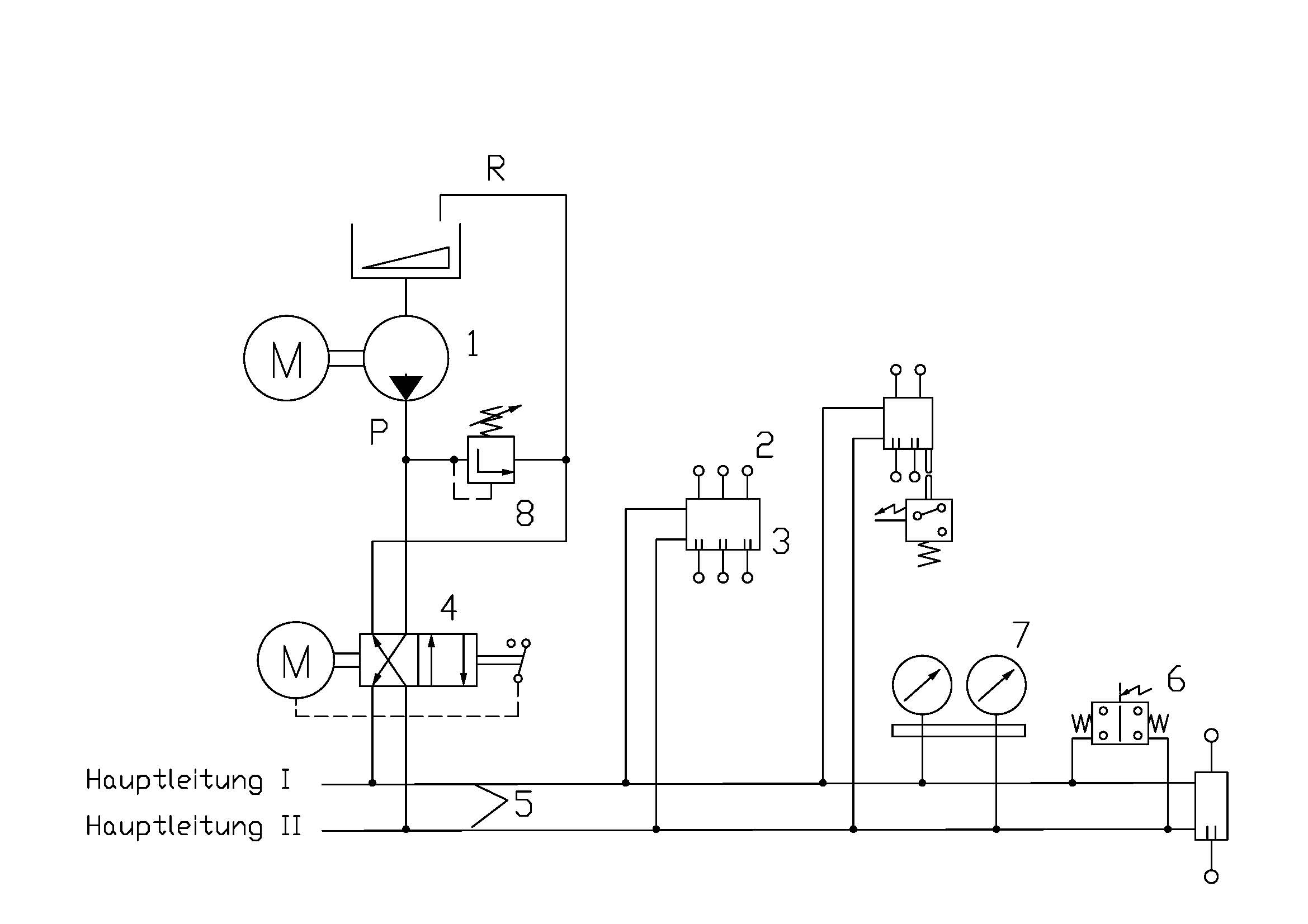

Dual Line Distributor Woerner Definition. dual line distributors are lubricant distributors in centralized lubrication systems. dual line distributors need two main lubricant lines in order to function. these lines are alternately supplied with lubricant by a pump unit. while one main line is pressurized, the other is relieved. for a complete lube cycle, both main lines. Location. office. nov 9, 2022. #12. professor fate said: yep, longer dwell keeps the spark hot at higher rpms, single point units can fade as the rpms climb. usually not an issue in day to day commuter cars, but is why you'll see them (factory) in rev happy commandos, 340s and other hipo engines of the day. cons are that good replacement parts. Fundamental differences. “on a v8 engine, you need eight crank pulses for every two engine revolutions. and with a cam signal, you need one pulse for every two engine revolutions,” says flynn. that’s what a dual sync distributor provides.”. here, the timing tables in the ecu essentially replace the archaic springs, weights, and vacuum. Definition. two main lines – in contrast to other centralized lubrication systems – are needed for dual line systems. both main lines together are also called a string. important applications for dual line systems (total loss lubrication systems) are: coking plants, foundries, continuous casting plants, hot and cold rolling mills.

So Funktioniert Ein Progressivverteiler What Really Happens Insideо Fundamental differences. “on a v8 engine, you need eight crank pulses for every two engine revolutions. and with a cam signal, you need one pulse for every two engine revolutions,” says flynn. that’s what a dual sync distributor provides.”. here, the timing tables in the ecu essentially replace the archaic springs, weights, and vacuum. Definition. two main lines – in contrast to other centralized lubrication systems – are needed for dual line systems. both main lines together are also called a string. important applications for dual line systems (total loss lubrication systems) are: coking plants, foundries, continuous casting plants, hot and cold rolling mills. The distributor rotor is a device in a spark ignition system that provides spark from the ignition coil for proper contact inside the distributor cap. it is driven by the camshaft of the engine and is therefore synchronized with it. as the camshaft rotates, the distributor shaft also rotates. this will cause the rotor attached to the. Using a dual point distributor what is the benefit?.

Zweileitungsverteiler Mit Fest Eingestelltem Dosiervolumen The distributor rotor is a device in a spark ignition system that provides spark from the ignition coil for proper contact inside the distributor cap. it is driven by the camshaft of the engine and is therefore synchronized with it. as the camshaft rotates, the distributor shaft also rotates. this will cause the rotor attached to the. Using a dual point distributor what is the benefit?.

Dual Line System Ttv Zentralschmiertechnik

Comments are closed.