So You Need A Good Surface Finish

So You Need A Good Surface Finish Youtube September 14, 2023. surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. surface finish can optimize a product’s performance, durability and the user experience and quality. this article will introduce the art and science of surface finish standards and surface finish. A 125 surface finish refers to a roughness average (ra) of 125 microinches (µin) or approximately 3.2 micrometers (µm). this level of finish is commonly found in general machining and offers a balance between cost effectiveness and good surface quality.

Basics Of Surface Finish вђ Gd T Basics In this section, we will embark on a comprehensive journey through 32 distinct surface finishes. from polished finishes like mirror and satin to textured finishes such as embossed and stippled, each finish brings a unique character to the material's surface. discover the applications, benefits, and techniques associated with these finishes. Surface finish is composed of three distinct elements – roughness, lay, and waviness (see figure 1 below). however, it is not uncommon in machine shops for the term surface finish to be used to describe only surface roughness. roughness is the most commonly specified aspect of surface finish, however, before we get into the details surface. If you can’t touch the surface but still need to measure it, you can use a non contact method, such as 3d metrology. whether the surface is hot or you can’t touch it for another reason, metrology can come in handy for measuring the surface finish. then, you can use a surface finishing chart to compare the surface to others like it. Passivation. passivation is a widely used chemical finishing process for stainless steel parts, involving acidic or basic chemical compounds to modify the metal surface. this process reduces corrosion, increases wear resistance, and improve aesthetics with a shiny finish. it also protects the surface from oxidation, preventing corrosion over time.

Understanding Surface Roughness And Surface Finish A Vrogue Co If you can’t touch the surface but still need to measure it, you can use a non contact method, such as 3d metrology. whether the surface is hot or you can’t touch it for another reason, metrology can come in handy for measuring the surface finish. then, you can use a surface finishing chart to compare the surface to others like it. Passivation. passivation is a widely used chemical finishing process for stainless steel parts, involving acidic or basic chemical compounds to modify the metal surface. this process reduces corrosion, increases wear resistance, and improve aesthetics with a shiny finish. it also protects the surface from oxidation, preventing corrosion over time. March 26, 2023 7 minutes of reading. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. the term “surface finish” is not defined correctly and tends to be used interchangeably by product designers and engineers with surface roughness, surface texture and surface. A 16 microinch rating is a high quality surface finish. it can only be done by buffing or honing the part after fabrication. this part will be smooth to the touch and tells the machinist that you care about the surface roughness a lot. a 1 microinch rating is the most extreme version of surface finish. it is the most refined surface finish that.

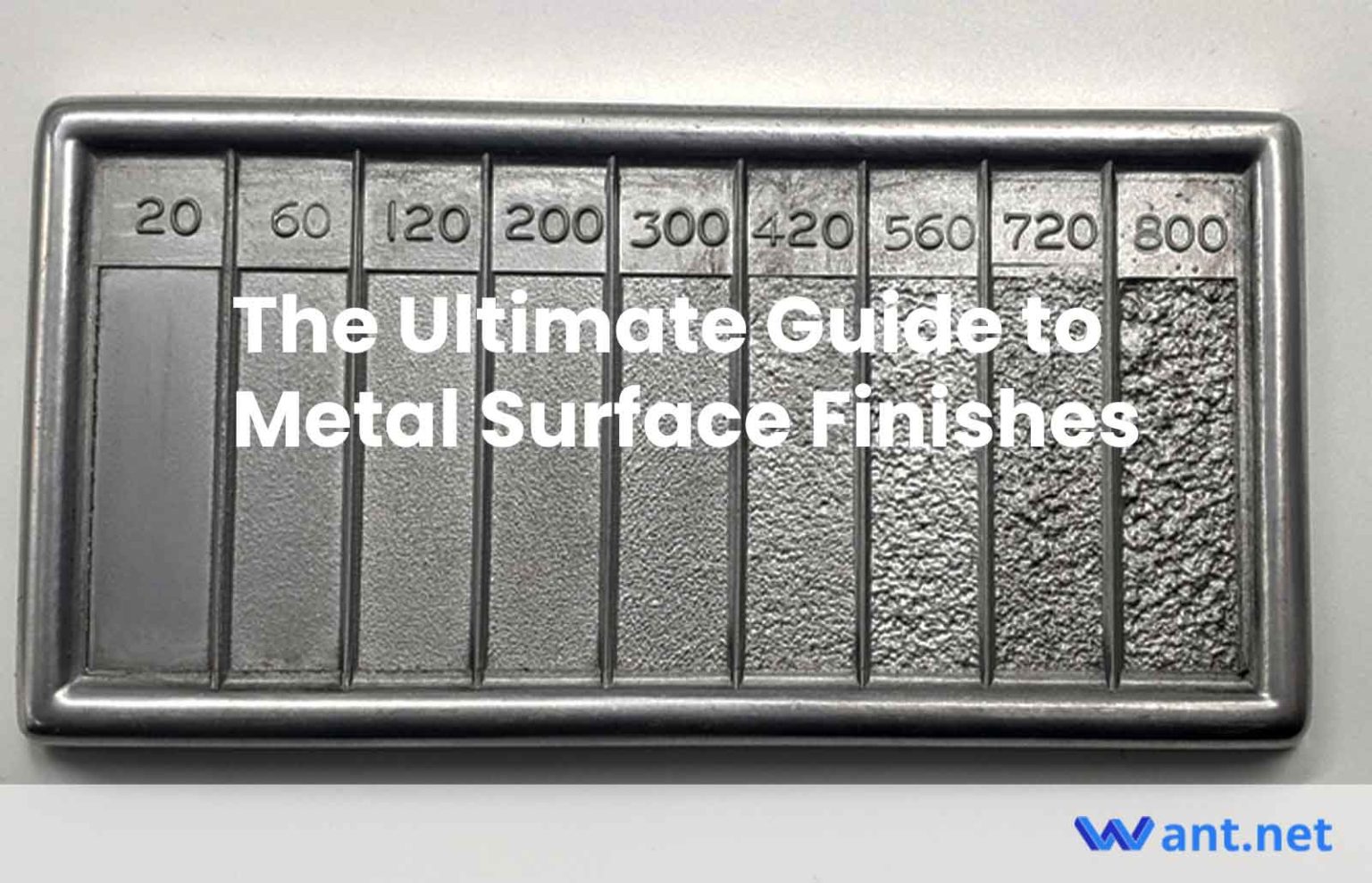

The Ultimate Guide To Metal Surface Finishes в Want Net March 26, 2023 7 minutes of reading. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. the term “surface finish” is not defined correctly and tends to be used interchangeably by product designers and engineers with surface roughness, surface texture and surface. A 16 microinch rating is a high quality surface finish. it can only be done by buffing or honing the part after fabrication. this part will be smooth to the touch and tells the machinist that you care about the surface roughness a lot. a 1 microinch rating is the most extreme version of surface finish. it is the most refined surface finish that.

125 Machine Surface Finish

Comments are closed.