Solved Ethylbenzene Is Converted To Styrene In The Catalytic Chegg

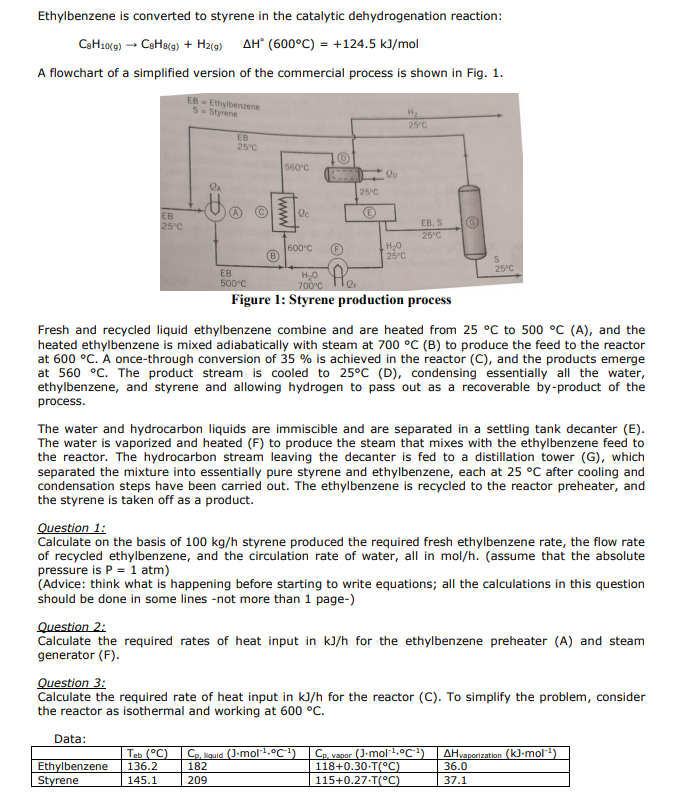

Solved Ethylbenzene Is Converted To Styrene In The Catalytic Chegg Ethylbenzene is converted to styrene in the catalytic dehydrogenation reaction cshn(g)→cshk(g) h2: Δh ^r∗(600′c)= 124.5 kj mol a flowchart of a simplified version of the commercial process is shown here. fresh and recycled liquid ethylbenzenc combine and are heated from 25∘c to 500∘c (a), and the heated ethylbenzene is mixed. See answer. question: ethylbenzene is converted to styrene in the catalytic dehydrogenation reaction csh₁0 (g) → cshs (g) h₂: aa (600°c) = 124.5 kj mol a flowchart of a simplified version of the commercial process is shown here. eb 25 c eb = ethylbenzene s = styrene qa eb 25°c a eb 500°c Ⓡ 560°c qc 600°c h₂o 700°c 10 po 25.

Solved Ethylbenzene Is Converted To Styrene In The Catalytic Chegg Here’s the best way to solve it. ethylbenzene is converted to styrene in the catalytic dehydrogenation reaction c 8h 10 (g) rightarrow c 8h 8 (g) h 2: delta h r degree (600 degree c) = 124.5 kj a flowchart of a simplified version of the commercial process is shown here. fresh and recycled liquid ethylbenzene combine and are heated from 25. Solar heat for the decarbonization of chemical industry: dehydrogenation of ethylbenzene to styrene driven by a concentrating solar power plant with molten salts as heat transfer fluids. energy conversion and management: x 2024 , 22 , 100546. On a basis of 100 \mathrm {~kg} \mathrm {h} 100 kg h styrene produced, calculate the required fresh ethylbenzene feed rate, the flow rate of recycled ethylbenzene, and the circulation rate of water, all in mol h. (assume p=1 \mathrm {~atm} p = 1 atm .) styrene is produced by catalytic dehydrogenation of ethylbenzene at high temperature in the. The ethylbenzene is recycled to the reactor preheater, and the styrene is taken off as a product. (a) on a basis of $100 \mathrm{kg} \mathrm{h}$ styrene produced, calculate the required fresh ethylbenzene feed rate, the flow rate of recycled ethylbenzene, and the circulation rate of water, all in mol h.

Solved Ethylbenzene Is Converted To Styrene In The Catalytic Chegg On a basis of 100 \mathrm {~kg} \mathrm {h} 100 kg h styrene produced, calculate the required fresh ethylbenzene feed rate, the flow rate of recycled ethylbenzene, and the circulation rate of water, all in mol h. (assume p=1 \mathrm {~atm} p = 1 atm .) styrene is produced by catalytic dehydrogenation of ethylbenzene at high temperature in the. The ethylbenzene is recycled to the reactor preheater, and the styrene is taken off as a product. (a) on a basis of $100 \mathrm{kg} \mathrm{h}$ styrene produced, calculate the required fresh ethylbenzene feed rate, the flow rate of recycled ethylbenzene, and the circulation rate of water, all in mol h. The majority of the adsorbed ethylbenzene is converted into styrene while only a fraction the adsorbed ethylbeneze have gone for cracking reaction to produce benzene and toluene. the “two type active sites” model assumed that there are two types of sites (x and z) for the adsorption of ethylbenze (x and z). A particular emphasis is given to the preparation of styrene from ethylbenzene dehydrogenation using co 2 as a soft oxidant because this method consumes co 2 (one of the greenhouse gases) and emerges as a green chemistry process. the detailed mechanism of ethylbenzene dehydrogenation into styrene using co 2 is studied.

Comments are closed.