Stud Wall Framing Dimensions Follow Accepted Building Techniques When

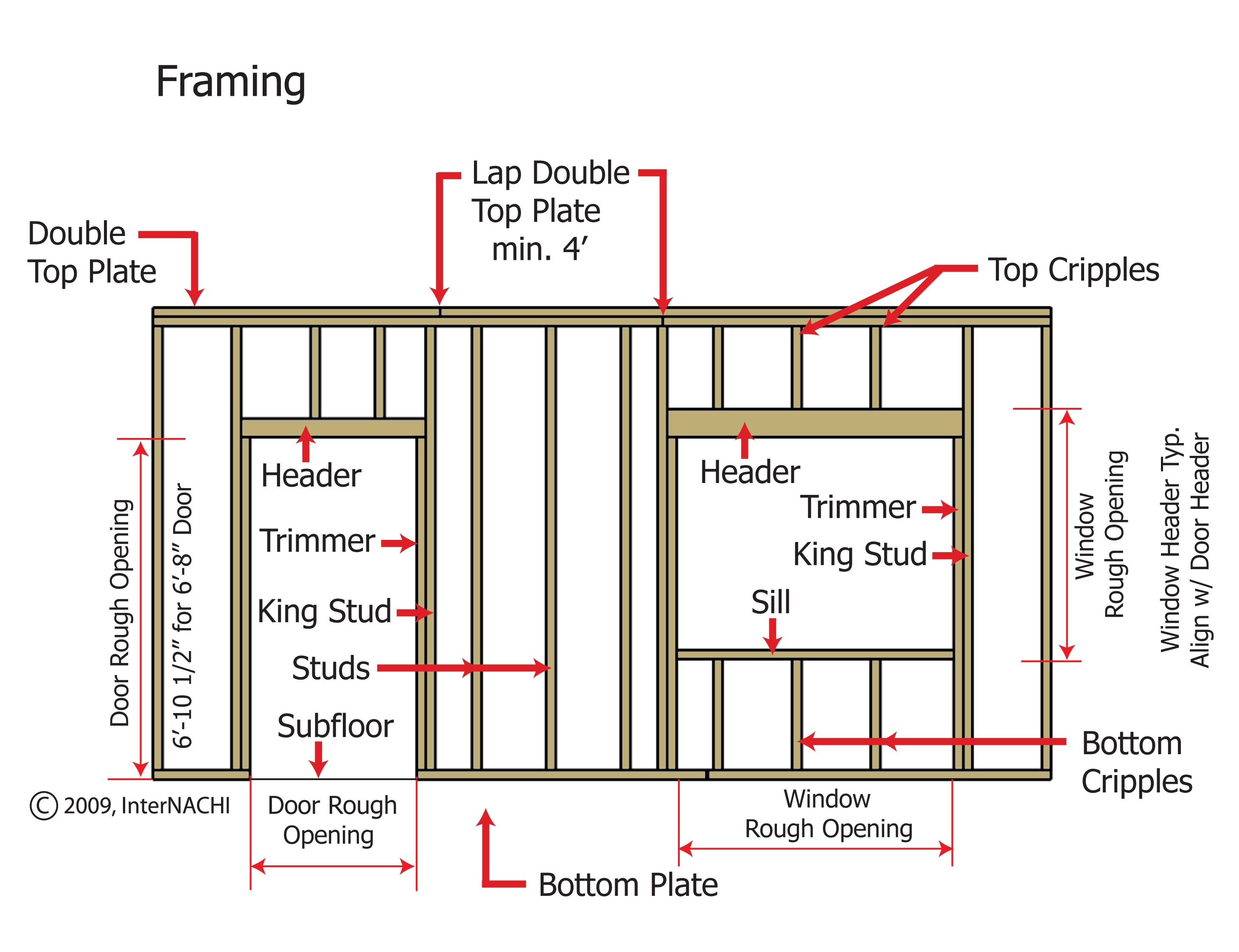

Stud Wall Framing Dimensions Follow Accepted Building Techniques When There are four things to consider when laying out a wall: load path, the location of intersecting walls, window and door openings and the king and jack (or trimmer) studs that outline their rough openings, and the common studs. watch this step by step video about laying out stud walls, and check out “building skills” in issue # 274 for more. There are good reasons to use precut studs. though they are not always available. i usually use precut studs to frame 8 ft. and 9 ft. tall walls. precut studs are shorter than the finished height of the wall to allow for the thickness of the bottom and top plates (the precut stud for an 8 ft. wall is actually 92 5 8 in.). a couple of years ago.

Stud Wall Framing Dimensions Follow Accepted Building Techniques When Advanced framing advanced framing with 2x6 wood studs spaced 24 inches on center, combined with wood structural panel sheathing, is one of the most cost effective solutions for builders trying to balance increasingly stringent energy codes with structural building code requirements. advanced framing is a system of framing techniques based. Step 2: measure and mark the plates. step 3: fasten the bottom plate. step 4: transfer the bottom plate location to the top plate location. step 5: install the studs. final thoughts. show 5 more. Train your eye. it’ll save time cutting, and as you develop, you’ll also be able to straighten walls as easily by eye as with a string. 7. finish one task before going on to the next. my first framing job was with a crew that would lay out, frame, and raise one wall at a time before moving on to the next. With the openings marked, lay out the stud locations. the goal is to position the studs every 16 or 24 in. so that the edges of 4×8 sheets of plywood align with the centers of studs. subtract 3 4 in. from the first layout mark. then hook your tape on a partially driven nail at this mark, and mark at each 16 or 24 in. multiple.

Basic Wall Framing Diagrams Printable Train your eye. it’ll save time cutting, and as you develop, you’ll also be able to straighten walls as easily by eye as with a string. 7. finish one task before going on to the next. my first framing job was with a crew that would lay out, frame, and raise one wall at a time before moving on to the next. With the openings marked, lay out the stud locations. the goal is to position the studs every 16 or 24 in. so that the edges of 4×8 sheets of plywood align with the centers of studs. subtract 3 4 in. from the first layout mark. then hook your tape on a partially driven nail at this mark, and mark at each 16 or 24 in. multiple. Mark identical spots on each board at 16 inch intervals. hold the studs in place one at a time and nail them into place through the top plate. (if any studs are warped, turn them so that the imperfect end is at the bottom.) repeat with the bottom plate, ensuring the edges of the studs are flush with the edges of the plate. Before you begin framing your corner, gather the following materials: 2x4s or 2x6s (depending on your wall thickness) 16d common nails. 8d common nails or 3 inch construction screws. drywall clips (for interior corners using the two stud method) rigid insulation or spray foam (for exterior corners) scrap lumber (if using as backing instead of.

Comments are closed.