Synthetic Sling Modern Safety Services

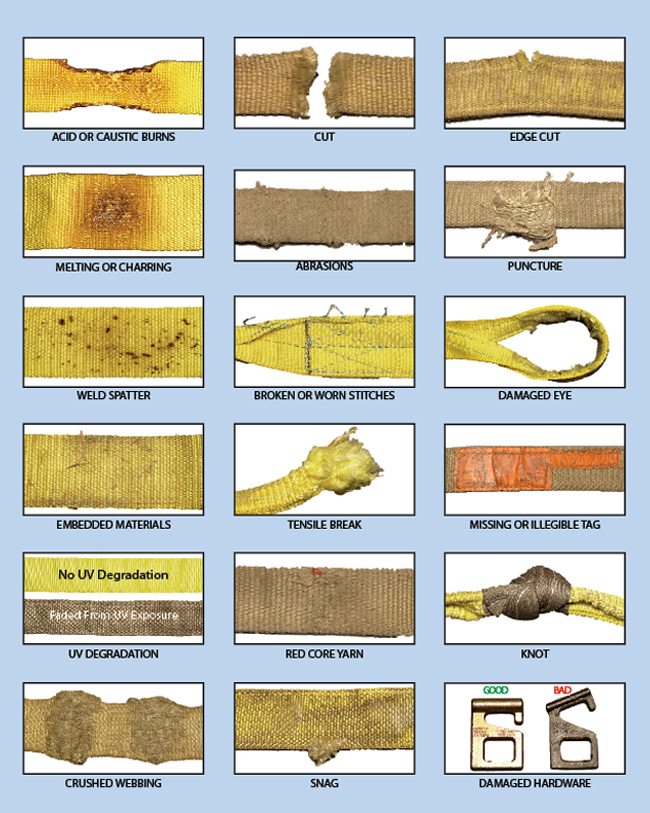

Synthetic Sling Modern Safety Services Synthetic web slings are easily cut and have poor abrasion resistance when compared with chain and wire rope slings. protect webbing from sharp corners, protrusions, or abrasive surfaces. protect slings from heat sources such as steam pipes, open flame and welding splatter. nylon slings are damaged by acids, but resist alkalis. Guidance on safe sling use synthetic web slings.

Protecting Your Synthetic Slings Protecting Your Life Crane Training However, you do need to consider a few things when using synthetic web slings. otherwise, you may risk damaging the load and or injuring your crew. 1. critical safety issues to consider when using synthetic web slings. web slings are a type of synthetic slings suitable for handling delicate and oddly shaped loads. There are two industry standards that exist to provide the end user with guidelines to inspect synthetic web slings and criteria that warrants removal from service: osha 1910.184 and asme b30.9. initial inspection (prior to initial use) best practice is to inspect synthetic web slings upon receiving them from the manufacturer. Shortening of the sling length. reduction in elasticity and strength of the sling material due to an exposure to sunlight, often evident by an accelerated abrasive damage to the surface yarn of the sling. breakage or damage to yarn fibers, often evident by a fuzzy appearance of the web. Web slings, roundslings, and polyester vs. nylon.

Comments are closed.