Techniques Of Gas Welding Parts Of Welding Torch Working Of Gas Weldingођ

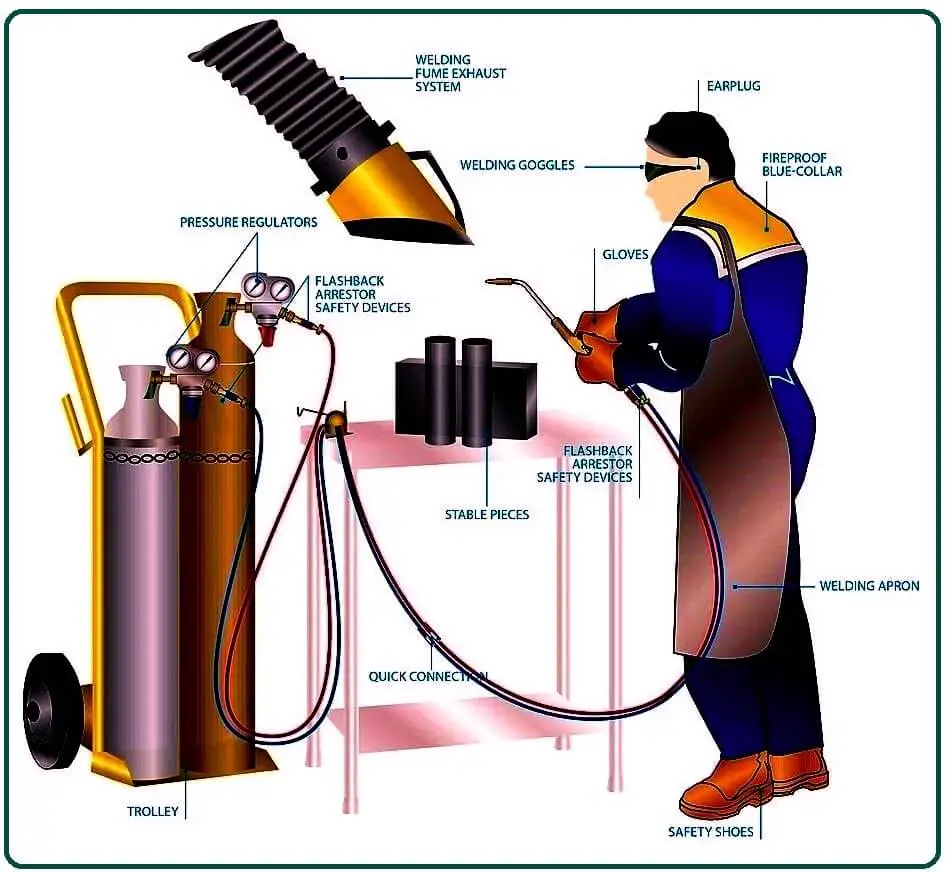

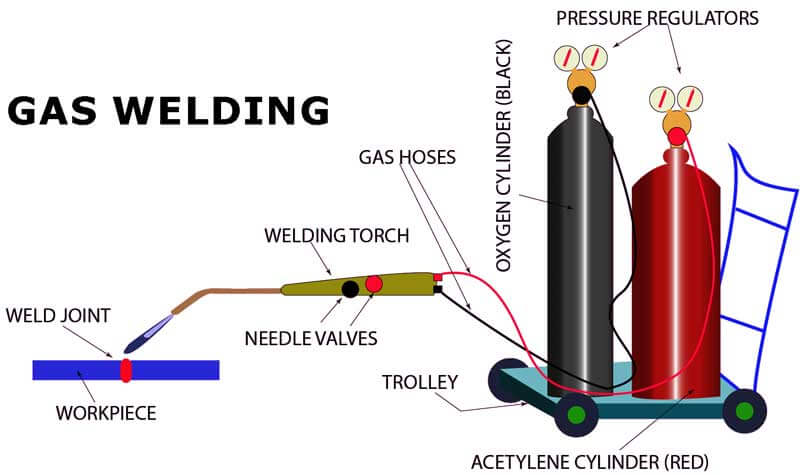

Techniques Of Gas Welding Parts Of Welding Torch Working о Techniques of gas welding: there are mainly four types of gas welding: #1. leftward or forward welding technique. in this welding technique, welding is initiated from the right side and proceeded to the left. when this technique is used, the welding torch is held in the right hand and the filler rod in the left hand. Gas welding is a widely used welding technique that utilizes a flame generated by the combustion of a fuel gas, such as acetylene or propane, mixed with oxygen. this section provides a detailed overview of the gas welding process and the essential equipment involved. a comprehensive guide to welding processes. 1.

What Is Gas Welding And Its Working Application Mech4study These acetylene and oxygen gas mixtures provide the highest flame temperature of all oxygen fuel gas mixtures. #2. oxy gasoline welding. when oxy gasoline welding is more effective than oxy acetylene when torch cutting of steel plates is done, gasoline can be applied to a hand pump with a pressure cylinder. #3. Gas welding is a type of liquid state welding process in which fuel gases burns to generate heat. this heat is further used to melt interface surfaces of welding plates which are held together to form a joint. in this process, mostly oxy acetylene gas is used as fuel gas. this process can be done with or without help of filler material. When the cutting part thickness is greater than or equal to 20mm, the flame should be shorter, and the distance should be appropriately reduced due to the slower gas cutting speed. 2. tempering of gas cutting (welding). (1) the hose for transporting gas is too long, too narrow, or too twisted. Gas welding is a process used to melt and then join metal parts, this involves fuel—specifically acetylene—in combination with oxygen to generate high temperature flames of up to 3,200 degrees celsius. due to its versatility, portability, and cost effectiveness, welding with gas is still one the most favored choices since other options.

Techniques Of Gas Welding Parts Of Welding Torch Working о When the cutting part thickness is greater than or equal to 20mm, the flame should be shorter, and the distance should be appropriately reduced due to the slower gas cutting speed. 2. tempering of gas cutting (welding). (1) the hose for transporting gas is too long, too narrow, or too twisted. Gas welding is a process used to melt and then join metal parts, this involves fuel—specifically acetylene—in combination with oxygen to generate high temperature flames of up to 3,200 degrees celsius. due to its versatility, portability, and cost effectiveness, welding with gas is still one the most favored choices since other options. Fundamentals of gas torch welding. gas torch welding is an art requiring skill and patience. it involves several basic techniques: fusion welding: joining metals by melting them together without filler. brazing: using a filler with a lower melting point than the base metals to join them. Oxy acetylene welding is a versatile and simple technique ideal for joining various ferrous and non ferrous metals, especially in small scale and hobbyist projects or repairs. gas welding offers control over different flame types— neutral, carburising, and oxidising —allowing adjustments to suit specific welding needs and material properties.

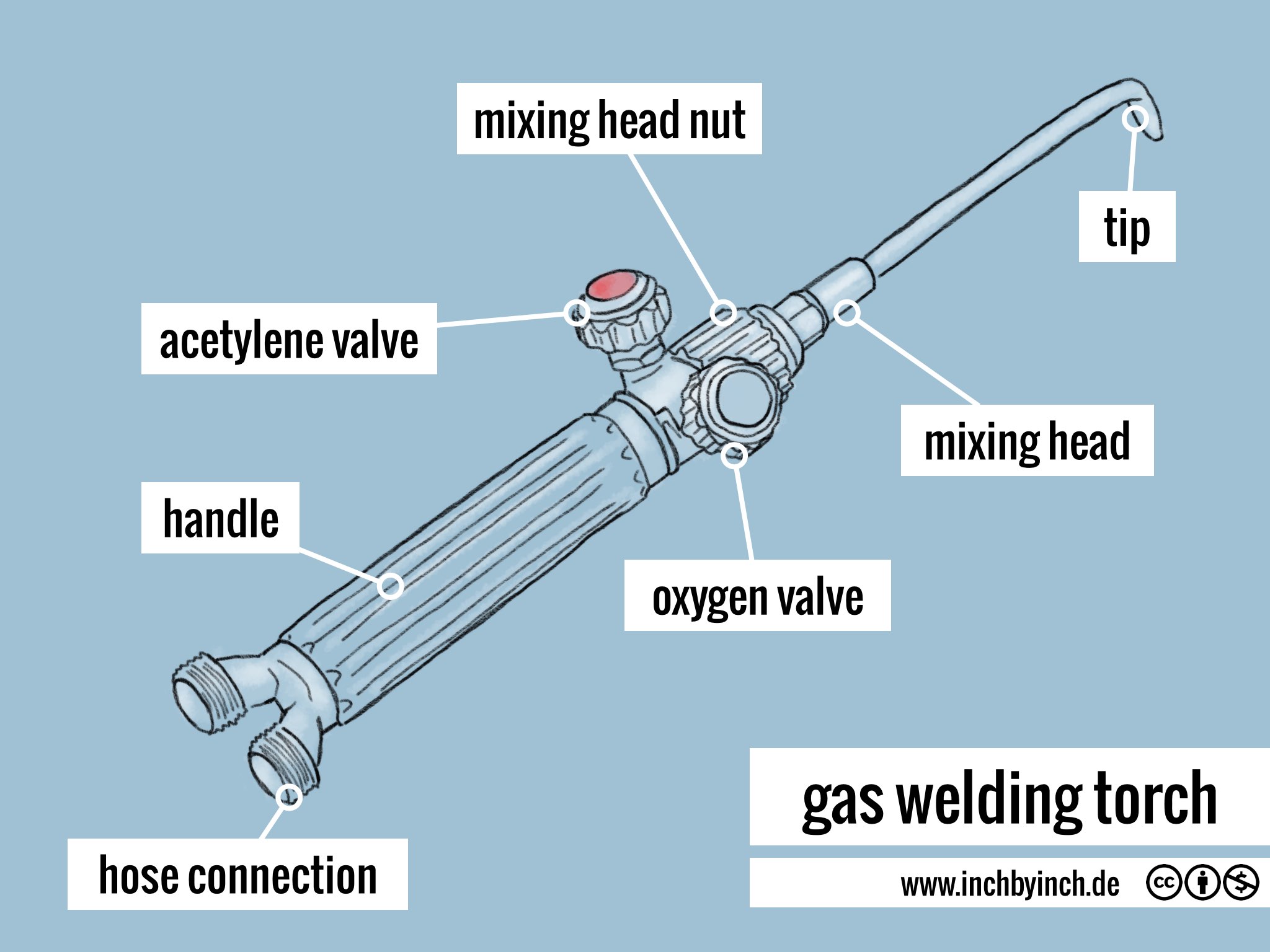

Inch Technical English Pictorial Gas Welding Torch Fundamentals of gas torch welding. gas torch welding is an art requiring skill and patience. it involves several basic techniques: fusion welding: joining metals by melting them together without filler. brazing: using a filler with a lower melting point than the base metals to join them. Oxy acetylene welding is a versatile and simple technique ideal for joining various ferrous and non ferrous metals, especially in small scale and hobbyist projects or repairs. gas welding offers control over different flame types— neutral, carburising, and oxidising —allowing adjustments to suit specific welding needs and material properties.

Techniques Of Gas Welding Parts Of Welding Torch Working о

Comments are closed.