The Function Of The Actuator In A Hydraulic System Stuffworking

Aircraft Actuators And Its Types The actuator is a converter or drives element in a hydraulic system. it is the component that converts hydraulic energy into mechanical energy. in any hydraulic system, our ultimate intention is to generate force and displacement at the user end. hence, we use actuators in the hydraulic system. let’s see different types of actuators. Hydraulic actuator definition is, a device that is used to change the fluid’s pressure energy into mechanical is known as a hydraulic actuator. the hydraulic actuator includes a cylinder or a fluid motor that works through hydraulic power for mechanical operation. the mechanical motion provides an output in the form of rotary, linear.

The Function Of The Actuator In A Hydraulic System Stuffworking Selecting the right hydraulic actuator. the selection of the hydraulic actuator will depend upon the application for which is it required. maximum force developed using a hydraulic cylinder depends on the maximum pressure the pump can generate and area of the actuator. since max pressure generated by pump is limited by the safe working pressure. The hydraulic actuator diagram is as shown below. hydraulic systems use the pump to push the hydraulic fluid through the system to create hydraulic power. the control valve that directs the flow controls the cylinder movement. it is possible to operate the control valve by electrical or manual modes. the fluid line pressure allows the piston to. Actuators are the devices that accept a control command and produce a change in the physical system by generating force, motion, heat, flow, etc. it is a device that makes something to move. normally, the actuators are used in conjunction with the power supply and a coupling mechanism. the power unit provides either ac or dc power at the rated. B) filter: this element filters the oil before going to the next element i.e. pump. c) pump: hydraulic pump is the heart of any hydraulic system. its main function is to create the flow of oil under pressure through the entire hydraulic system and hence to assist the transfer of power and motion (i.e. useful work).

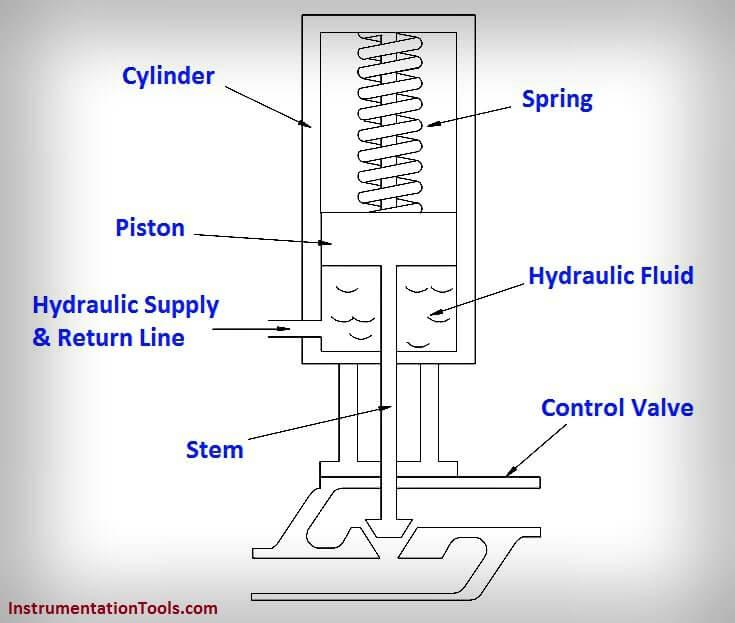

The Function Of The Actuator In A Hydraulic System Stuffworking Actuators are the devices that accept a control command and produce a change in the physical system by generating force, motion, heat, flow, etc. it is a device that makes something to move. normally, the actuators are used in conjunction with the power supply and a coupling mechanism. the power unit provides either ac or dc power at the rated. B) filter: this element filters the oil before going to the next element i.e. pump. c) pump: hydraulic pump is the heart of any hydraulic system. its main function is to create the flow of oil under pressure through the entire hydraulic system and hence to assist the transfer of power and motion (i.e. useful work). Hydraulic actuators use liquid pressure rather than instrument air pressure to apply force on the diaphragm to move the valve actuator and then to position valve stem. nearly all hydraulic actuator designs use a piston rather than a diaphragm to convert fluid pressure into mechanical force. the high pressure rating of piston actuators lends. 1. linear actuator: for linear actuation (hydraulic cylinders). 2. rotary actuator: for rotary actuation (hydraulic motor). 3. semi rotary actuator: for limited angle of actuation (semi rotary actuator). hydraulic linear actuators, as their name implies, provide motion in a straight line. the total movement is a finite amount determined by the.

What Is A Hydraulic Actuator Instrumentation Tools Hydraulic actuators use liquid pressure rather than instrument air pressure to apply force on the diaphragm to move the valve actuator and then to position valve stem. nearly all hydraulic actuator designs use a piston rather than a diaphragm to convert fluid pressure into mechanical force. the high pressure rating of piston actuators lends. 1. linear actuator: for linear actuation (hydraulic cylinders). 2. rotary actuator: for rotary actuation (hydraulic motor). 3. semi rotary actuator: for limited angle of actuation (semi rotary actuator). hydraulic linear actuators, as their name implies, provide motion in a straight line. the total movement is a finite amount determined by the.

Comments are closed.