Troubleshooting Guide To 19 Common 3d Printing Problems Part Two

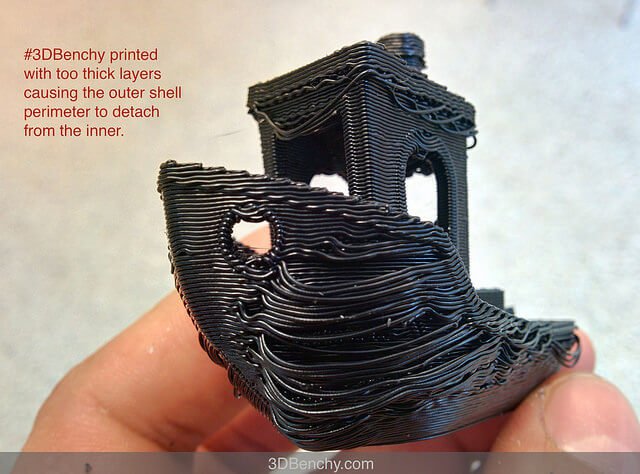

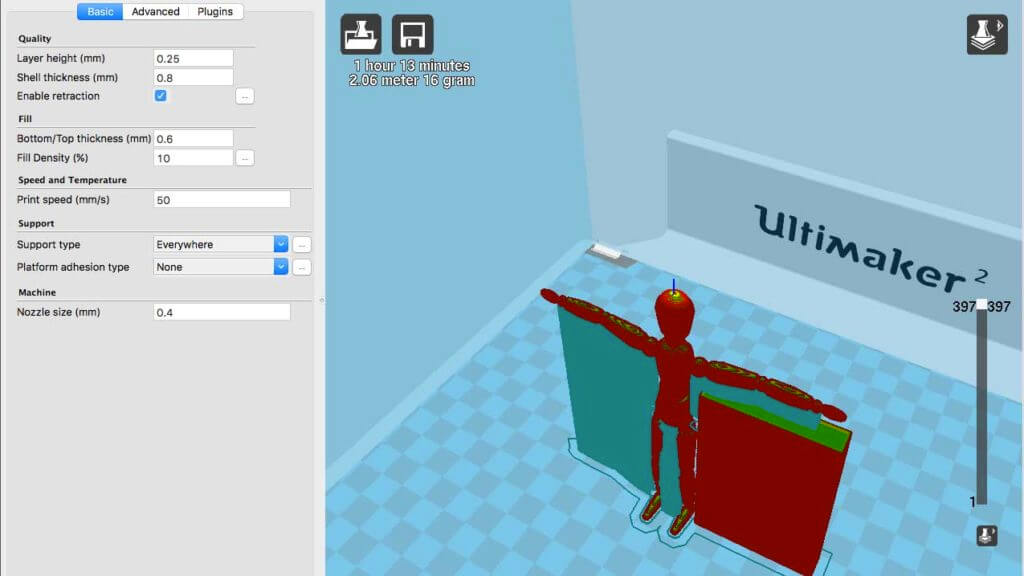

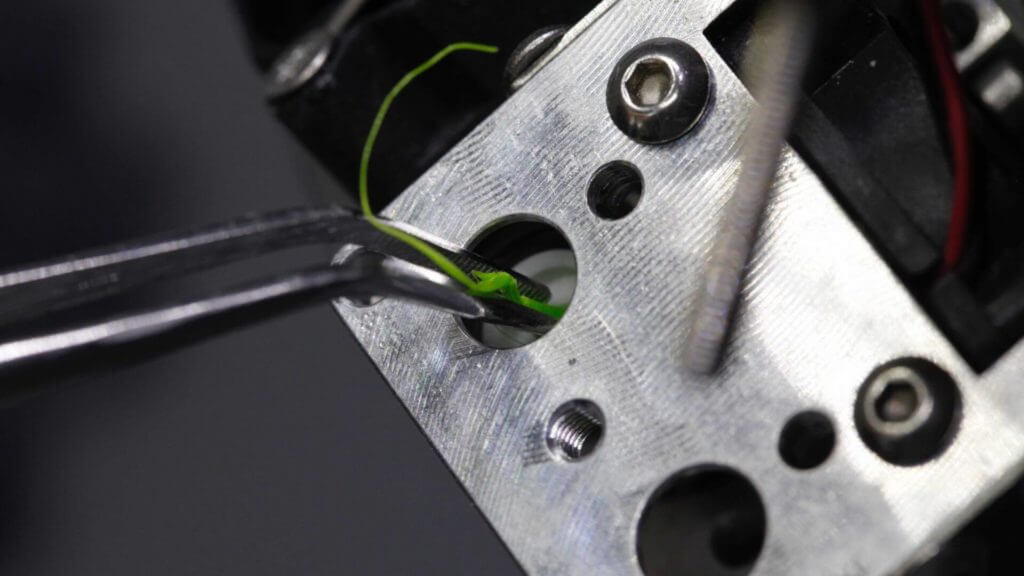

Troubleshooting Guide To 19 Common 3d Printing Problems Part Two This is one of the most common issues with many 3d printers. if your adhesion is lacking, you might end up with warped print – or no print at all besides a huge mess of tangled filament on your bed (e.g. green ‘birds nest’ print you see here). many common 3d printing problems stem from a poor first layer. the following are the various. 3d printer troubleshooting: gaps between infill and outer wall. check the infill overlap. this is by far the most common issue and is easy to resolve. in your slicing software locate the ‘infill overlap’ option and increase the value. in cura by default, this is set to 15% so raise it to 30%.

Troubleshooting Guide To 19 Common 3d Printing Problems Part Two вђ Geeetech 3d printer troubleshooting: pillowing. filament size. more common with 1.75 mm filament. pillowing is an issue that can affect all 3d printers, however, it’s far more common on those using 1.75 mm filament over 2.85mm. check the fan position. cooling is normally the issue start by checking your fans. 3d printing troubleshooting: 15 most common problems &. 3d printer troubleshooting guide. 3d printing troubleshooting: all problems & solutions.

Troubleshooting Guide To 19 Common 3d Printing Problems Part Two вђ Geeetech 3d printer troubleshooting guide. 3d printing troubleshooting: all problems & solutions. Solutions for this 3d printing error: isopropyl alcohol bath: before removing the support structures, wash the object thoroughly with isopropyl alcohol. this removes liquid resin residue and prepares the model for the next step. using hot water: soak the model in hot water to soften the support structures. How to fix the most common 3d printing errors prusa blog.

Comments are closed.