Tutorial Synchronization Of Hydraulic Cylinders Without Regulation And Without Proportional Valve

Tutorial Synchronization Of Hydraulic Cylinders Without Regulationо Tutorial about synchronization of hydraulic cylinders without regulation and without proportional valve.related video: watch?v=qyb164b. Hydraulic valves and controls play an important role in enabling cylinder synchronization within a hydraulic system. components like directional control valves actively regulate and direct the flow of hydraulic fluid to synchronize cylinder movements. flow control valves manage the speed and rate of fluid flow to ensure smooth, controlled motion.

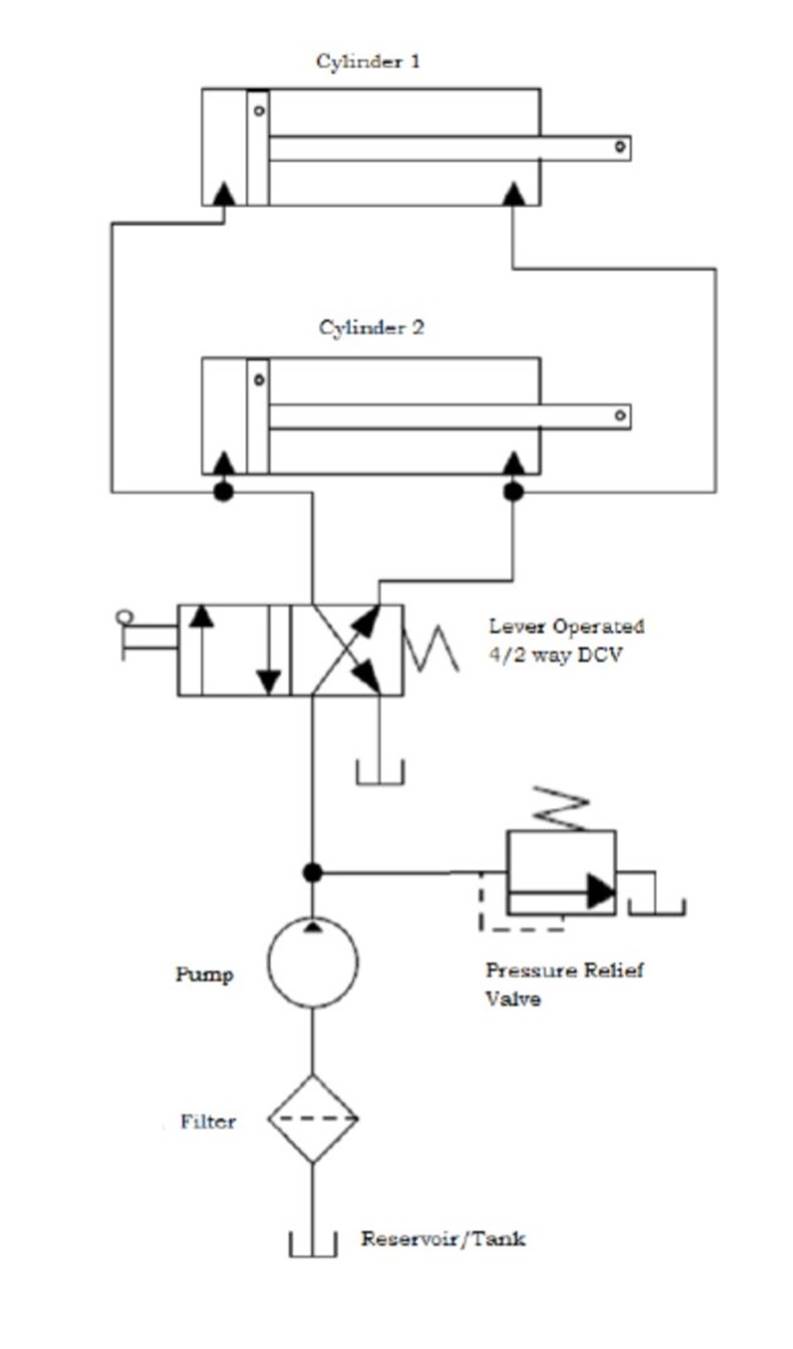

Solved Design And Testing Of Hydraulic Cylinder Synchronization All sensors in the system communicate with one another, and cylinders always know where they are in relation to the others. if one cylinder moves ahead, the valve will close and automatically bring it back into synchronization. exact operations will vary depending on the specifications and configuration of your position sensing cylinders. Double pump and valve synchronizing circuit. figures 22 15 through 18 illustrate a common way of synchronizing cylinders. many designers use this circuit and consider it to be one of the best ways to synchronize cylinders. it is reasonably accurate, but may allow the cylinders to get out of phase in certain conditions. Mentored engineer. durham, nc 27712. phone: (919) 808 6276. email: contact us. all content featured by the mentored engineer is for educational purposes. the mentored engineer does not practice engineering nor does it claim responsibility for designs based on content posted. This means that the proportional valve will in troduce problems when this feedback loop is also active when the proportional valve is in the cen ter position. if accurate control near the center position of the proportional valve is required, the engineer should consider the more expensive and sensitive servo valves. 2.4 connect cylinders to.

How To Synchronize Hydraulic Cylinders Cylinders Inc Mentored engineer. durham, nc 27712. phone: (919) 808 6276. email: contact us. all content featured by the mentored engineer is for educational purposes. the mentored engineer does not practice engineering nor does it claim responsibility for designs based on content posted. This means that the proportional valve will in troduce problems when this feedback loop is also active when the proportional valve is in the cen ter position. if accurate control near the center position of the proportional valve is required, the engineer should consider the more expensive and sensitive servo valves. 2.4 connect cylinders to. The hydraulic cylinder will encounter impact load during its movement, which will cause hydraulic impact on the system and affect the stability of the hydraulic cylinder speed. in the simulation model, the load pressure is set to 5 mpa, and the air content of the hydraulic oil is set to 10 and 20%. When we talk about "synchronizing cylinders", we are talking about the ability to have two or more hydraulic cylinders operate at the same time and rate while maintaining their relative positions, regardless of the external forces acting against them. synchronizing hydraulic cylinders is essential if you intend to lift a load using multiple lifting points. while.

Comments are closed.