What Are Single Acting Pneumatic Cylinders

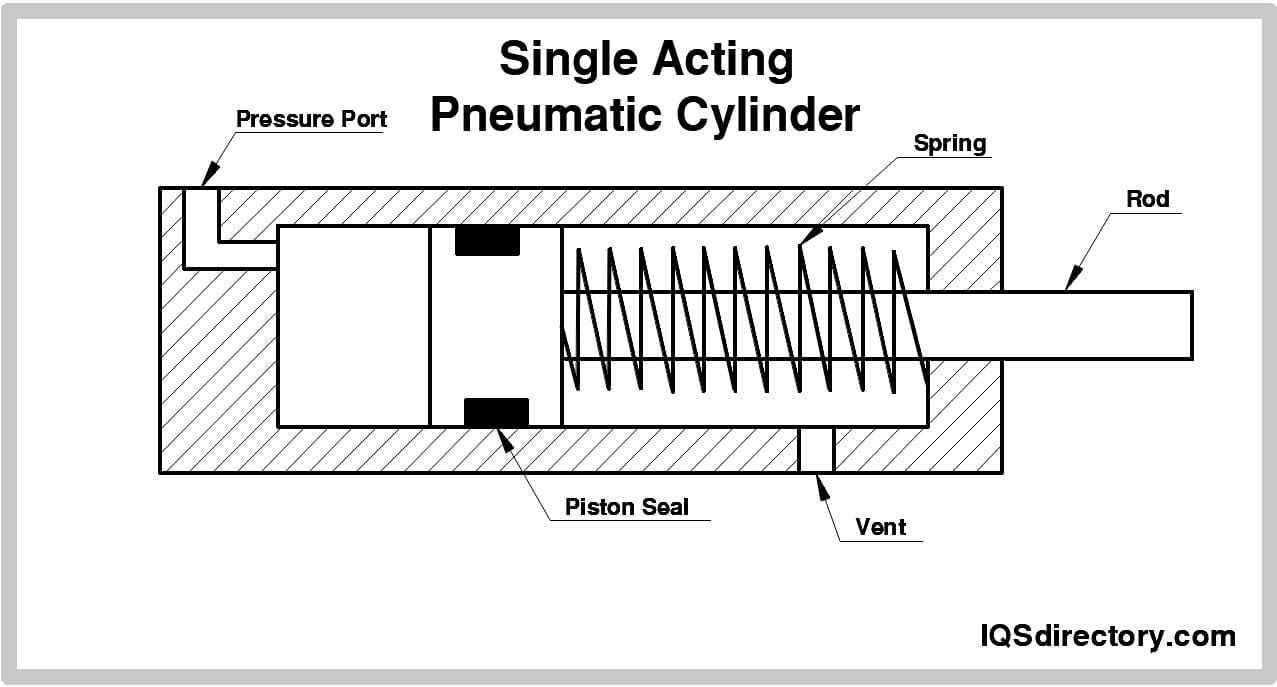

What Are Single Acting Pneumatic Cylinders 45 Off Single acting air cylinders work by using air pressure on one side of a piston to move it. once the air pressure is gone, a spring inside the cylinder pushes the piston back to where it started. this design is simple but effective, relying on both air pressure and a spring to function. the piston seals are crucial. In single acting pneumatic cylinders, air is supplied through one port to one side of the piston, causing the piston rod to extend in one direction for a task such as lifting an object. the other side vents air to the environment. movement in the opposite direction occurs most often by means of a mechanical spring, which returns the piston rod.

Ma Series Single Acting Pneumatic Cylinder Aluminum Alloy Tube With One of the disadvantages of single acting pneumatic cylinders is the inconsistent output stroke. because a mechanical spring is used as the opposing force it may eventually wear. this results in an inconsistent output stroke length from the cylinder. single acting air cylinders would not be used in applications where precision is required. What is a single acting pneumatic cylinder? as the name suggests, a single acting pneumatic cylinder is an actuator that uses a pneumatic system to convert pressure into movement and features a single acting design. pneumatic systems use pressurized air or another gas as the agent for converting energy from one source into motion of the actuator. A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion. learn about double acting pneumatic air cylinders, single acting cylinders, iso standards, and more. It provides higher force than other cylinders because of the two double acting cylinders connected during the actuation. 4.telescopic cylinder. this one uses segmented tubes and provides longer strokes since it is telescopic in detail. the working procedure begins when the pressurized air fills the cylinder, and the tubes eventually extend.

Comments are closed.