What Is 6g Welding Updated On 2024

Pin On Mb 55 Off Www Gf Planen De 6g welding certification is a difficult certification test that welders must pass in order to become certified. the test is difficult because the pipe is at a 45 degree angle and immovable. welders must be able to weld in all positions, including horizontal, vertical and overhead. they may also have to weld both right handed and left handed. 6g welding is a welding position in which the welder is required to weld in a horizontal position while upside down. this position is considered one of the most difficult and challenging welding positions, as it requires a high level of skill and precision. the types of materials that are typically used in 6g welding include carbon steel and.

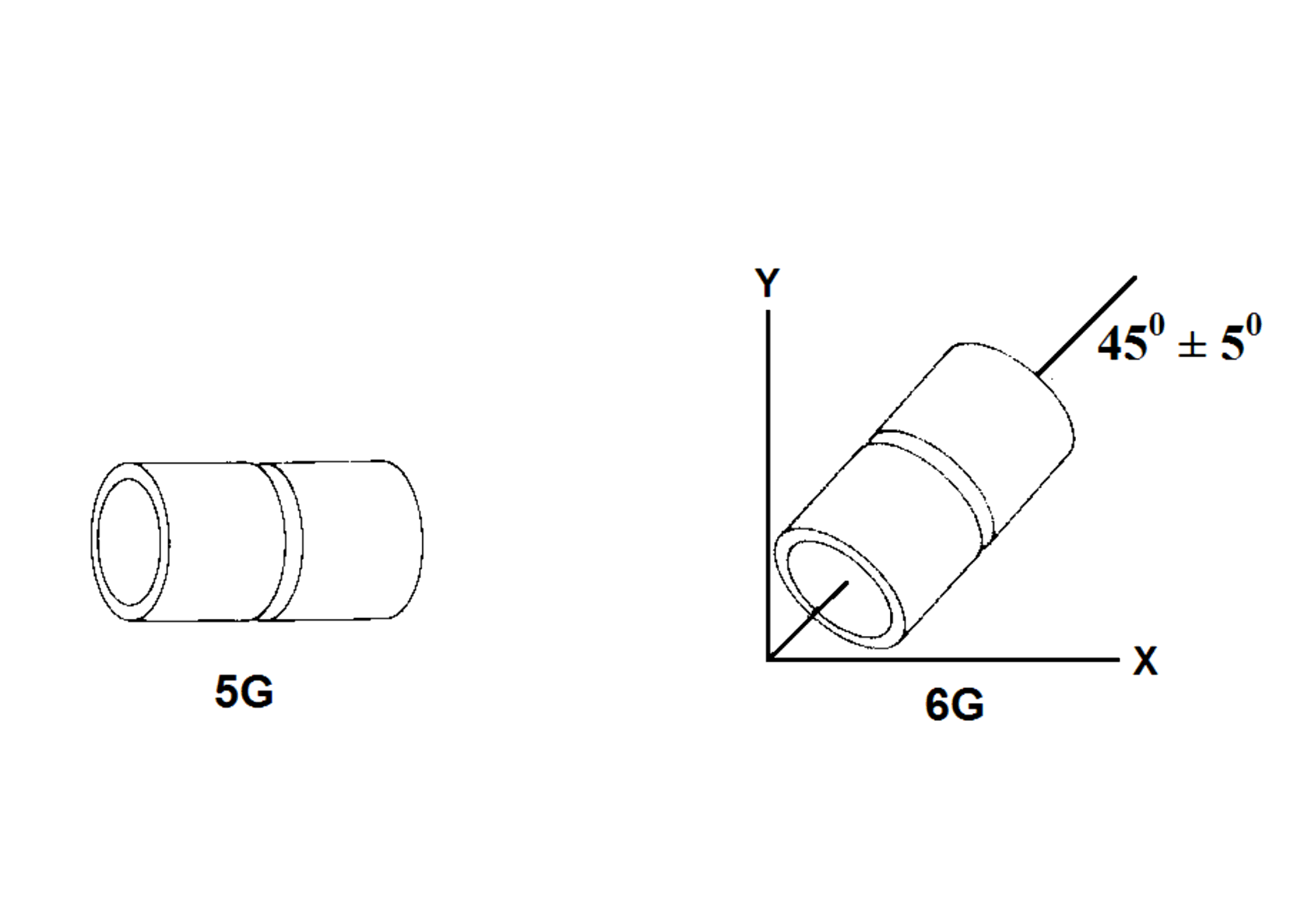

Pipe Welding Guide Here S How To Pass A Smaw 6g Welding Certification A 6g weld test is a type of pipe welding test where the pipe is welded in a fixed position with the axis of the pipe at a 45 degree angle. this means that the pipe cannot be rolled or moved once welding begins. this test is used to evaluate a welder’s ability to produce a sound weld in the 6g position. the test is also used to assess a welder. 6g in welding is a challenging and advanced position used for pipe welding. it requires welders to work on a pipe fixed at a 45 degree angle, making it difficult to access all areas. this position tests a welder’s skills and precision. mastery of 6g welding is crucial for high quality, durable welds, especially in industries like oil, gas. The 6g welding position is the ultimate challenge for welders. it is considered the most perplexing position in groove welding, requiring a high degree of proficiency, experience, and precision. in this position, the welder must work on a pipe that is inclined at a 45 degree angle and rotated while welding. The 6g pipe weld position is one of the most difficult welding certification examinations to pass since the pipe is at the 45 degree position, making it impossible to move. welders trying to get a passing grade on the 6g certification test must weld in all of the positions, including horizontal, vertical, overhead, left handed, and right handed.

5 Types Of Welding Positions 1g 2f 3g 4g The 6g welding position is the ultimate challenge for welders. it is considered the most perplexing position in groove welding, requiring a high degree of proficiency, experience, and precision. in this position, the welder must work on a pipe that is inclined at a 45 degree angle and rotated while welding. The 6g pipe weld position is one of the most difficult welding certification examinations to pass since the pipe is at the 45 degree position, making it impossible to move. welders trying to get a passing grade on the 6g certification test must weld in all of the positions, including horizontal, vertical, overhead, left handed, and right handed. The nomenclature “6gr” is derived from industry standard welding position codes: “6” denotes the 45° fixed inclined position. “g” represents “groove,” indicating a full penetration weld joint. “r” signifies the presence of the restricting obstacle ring. this welding configuration is particularly relevant for pipeline. Pipe welding and everything you need to know how to stick weld pipe to pass a 6g (open root) pipe welding certification. covering bevel set up, tack welding, e6010 open root, e7018 hot pass and cap. with detailed accurate information and pictures of the electrode angles, machine set up, pipe welding techniques, and the entire welding certification from start to finish!.

Welding Position 1g 2g 3g 4g 5g Pdf Hondacrvblog The nomenclature “6gr” is derived from industry standard welding position codes: “6” denotes the 45° fixed inclined position. “g” represents “groove,” indicating a full penetration weld joint. “r” signifies the presence of the restricting obstacle ring. this welding configuration is particularly relevant for pipeline. Pipe welding and everything you need to know how to stick weld pipe to pass a 6g (open root) pipe welding certification. covering bevel set up, tack welding, e6010 open root, e7018 hot pass and cap. with detailed accurate information and pictures of the electrode angles, machine set up, pipe welding techniques, and the entire welding certification from start to finish!.

Welding Positions 4 Main Types Weld Guru Vrogue Co

Comments are closed.