What Is Electroplating Copper Electroplating

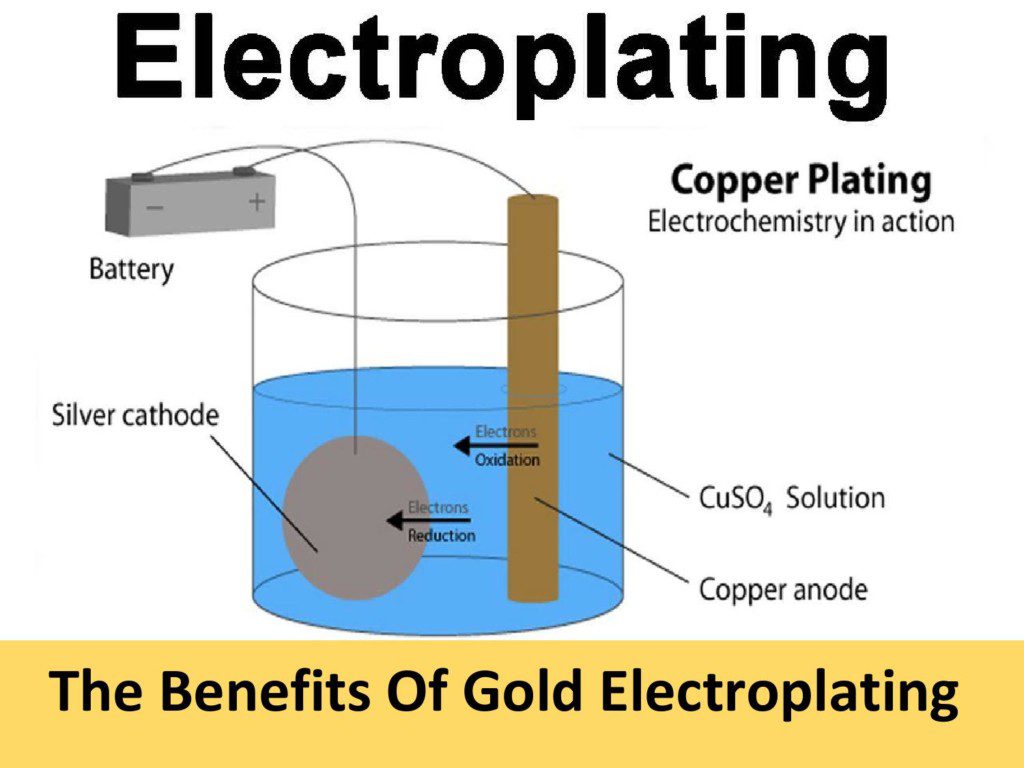

Electric Plating Copper Diagram Copper electroplating. copper electroplating is the process of electroplating a layer of copper onto the surface of a metal object. copper is used both as a standalone coating and as an undercoat onto which other metals are subsequently plated. [1] the copper layer can be decorative, provide corrosion resistance, increase electrical and thermal. Copper electroplating bath. the concept of copper electroplating is straightforward: submerge the wafer to be plated into an electrolyte bath, apply a current, and copper ions will migrate and deposit onto regions with a pre existing metal seed layer. figure 1: image of electrolytic plating cell. the electrolyte bath contains three primary.

What Is Electroplating Definition Working Principle Its Uses Copper electroplating is a simple electrochemical process that results in a thin copper coating on any conductive surface with the help of an electrolyte bath. the electrolysis process is quite simple. Electroplating example . a simple example of the electroplating process is the electroplating of copper in which the metal to be plated (copper) is used as the anode, and the electrolyte solution contains the ion of the metal to be plated (cu 2 in this example). copper goes into solution at the anode as it is plated at the cathode. Electroplating. copper electroplating machine for layering pcbs. electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. the part to be coated acts as the cathode (negative. Electroplating takes a substrate material (often a lighter and or lower cost material) and encapsulates the substrate in a thin shell of metal, such as nickel or copper. electroplating is most commonly applied to other metals, because of the basic requirement that the underlying material (the substrate) is conductive.

Copper Electroplating Fundamentals Electroplating. copper electroplating machine for layering pcbs. electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. the part to be coated acts as the cathode (negative. Electroplating takes a substrate material (often a lighter and or lower cost material) and encapsulates the substrate in a thin shell of metal, such as nickel or copper. electroplating is most commonly applied to other metals, because of the basic requirement that the underlying material (the substrate) is conductive. Electroplating is a type of plating, but it differs from other plating methods because it uses an electric current to move ions from a solution onto the surface of the metal. this process creates a thin, even layer of plating that adheres to the surface. this layer is usually made up of a metal such as copper, gold, silver, or nickel. Copper electroplating process. copper electroplating is coating a thin copper film on a metal substrate. you can carry out the process in copper sulfate electrolysis. the material to be plated is submerged in the solution of copper ions as it acts as a cathode, and copper rod wire acts as an anode.

Comments are closed.