What Is The Pneumatic Actuator Working Principle

Pneumatic Valve Actuator Working Principle Control Valves Engineers By definition, a pneumatic actuator is a device that converts energy typically in the form of compressed air into mechanical motion. within the industry, pneumatic actuators are recognised by several different names including pneumatic cylinders, air cylinders, and air actuators; all of which are one and the same. A pneumatic actuator is a mechanism that uses air pressure to move, position, or control the operation of a device. “pneumatic” means air based, while “an actuator” is any device that causes something to move. depending on the type, a pneumatic force actuator may push a load, pull it along a straight line, or cause it to rotate.

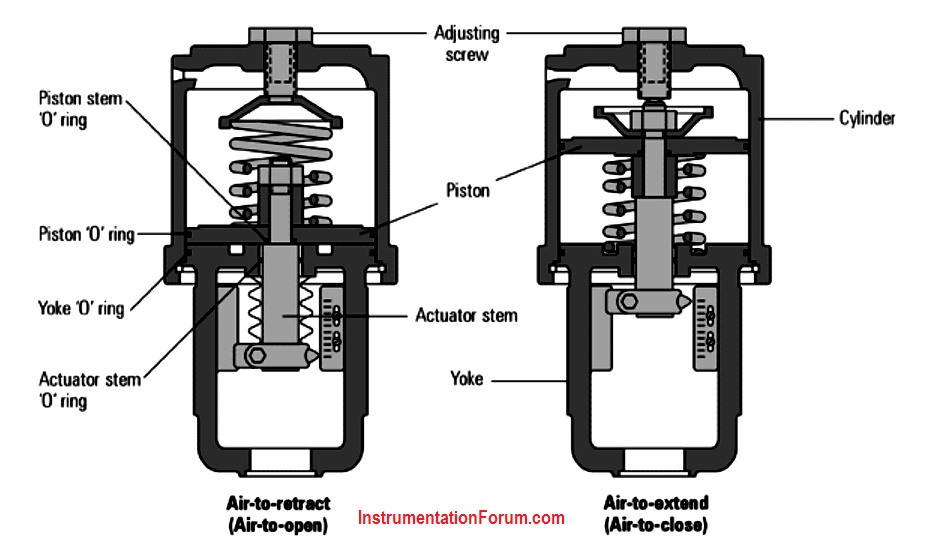

What Are Pneumatic Actuators Principle Working Advant Vrogue Co Definition: the actuators that are designed to operate on compressible fluid generally air, is known as pneumatic actuator. the pneumatic actuators use the pressurized air as input and change it into mechanical motion. more specifically, pneumatic actuators are devices that change the pressure obtained by compressing the air into mechanical energy. They operate on the basic principle of using compressed air to drive a piston or gear, converting energy into mechanical motion with high efficiency and reliability. pneumatic actuators are relevant in numerous fields, from manufacturing to aerospace. in factories, they control machinery with precision, improving productivity and safety. Working principle of pneumatic actuators. by editorial staff. pneumatic actuators use instrument air pressure to apply force on the diaphragm to move the valve actuator and then to position valve stem. the following photograph shows a cut away control valve, with a pneumatic diaphragm actuator mounted above the valve body. Pneumatic rack and pinion actuators for valve controls of water pipes. a pneumatic actuator mainly consists of a piston or a diaphragm which develops the motive power. it keeps the air in the upper portion of the cylinder, allowing air pressure to force the diaphragm or piston to move the valve stem or rotate the valve control element.

Working Principle Of Pneumatic Actuators Parts Of Pneumatic Actuator Working principle of pneumatic actuators. by editorial staff. pneumatic actuators use instrument air pressure to apply force on the diaphragm to move the valve actuator and then to position valve stem. the following photograph shows a cut away control valve, with a pneumatic diaphragm actuator mounted above the valve body. Pneumatic rack and pinion actuators for valve controls of water pipes. a pneumatic actuator mainly consists of a piston or a diaphragm which develops the motive power. it keeps the air in the upper portion of the cylinder, allowing air pressure to force the diaphragm or piston to move the valve stem or rotate the valve control element. Pneumatic actuators are categorized by their type of motion. they are either linear or rotary. a linear pneumatic actuator can move something in a straight line. for example, a rod is moved in and out of a cylinder in a linear motion by a pneumatic energy source. a rotary pneumatic actuator can make something move in a circular motion. The pneumatic actuator is constructed by using different components like a spring, compressor, reservoir, diaphragm, and valve. the following diagram represents the construction of a pneumatic actuator. to drive this system, the energy of the fluid is changed to mechanical. in this system, the fresh air is compressed through the compressor.

Comments are closed.