What No One Is Willing To Tell You About Laser Welding Expensive Novelty Or Must Have

Laser Welding Novelty Steel Follow along the progress of the table laser here! indiegogo projects herolaser t1 lightest 5 in 1 ai table laser welder coming soonto learn. Simply put, laser welding is a process in which lasers are used to melt the material on the surface of a workpiece, allowing it to be joined to another workpiece made of the same material. laser welding is typically done for either metals or thermoplastics. different types of lasers have also been used for welding, with older applications using.

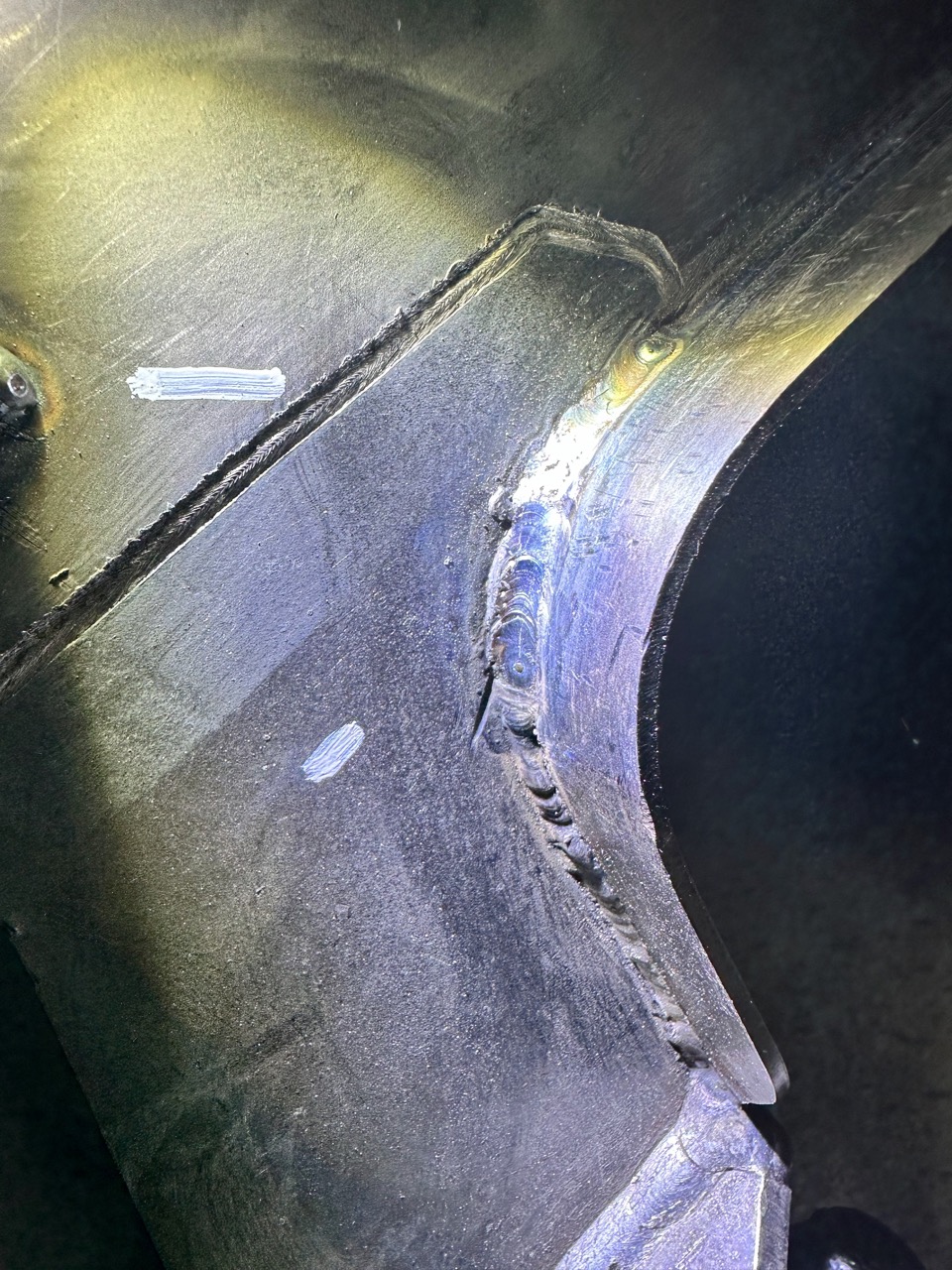

Laser Welding A Brief Introductory Guide As the energy from the laser beam is absorbed by the surface, the heat causes the surface to melt, forming a molten pool that resolidifies in a few milliseconds. think of laser welding like a magnifying glass and the sun. if you focus enough energy on a metal surface, you can melt it—and even vaporize it in some cases. 2. suitable for a wide range of materials and thicknesses. with the latest laser welding technology, you can weld materials such as stainless steel, aluminum, titanium and nickel alloys, thermoplastics, and other textures such as wood. the laser welding system allows you to weld materials ranging from 1 30 mm. 1. laser brazing. the principle of laser brazing welding is as follows: the laser beam is used as the heat source, and the focused beam is directed onto the surface of the filler wire. the wire is continuously heated by the beam energy, causing it to melt and form a high temperature liquid metal. Mid ranged fiber laser welders. you’ll see a lot of variety from $20,000 to $100,000 in this price range. mid range machines range from high quality handheld laser welders to automatic cnc laser welders with 2 3kw lasers. a mid level welding machine is best suited to factories that perform welding operations daily.

The Most Expensive Welding Machine In The World 1. laser brazing. the principle of laser brazing welding is as follows: the laser beam is used as the heat source, and the focused beam is directed onto the surface of the filler wire. the wire is continuously heated by the beam energy, causing it to melt and form a high temperature liquid metal. Mid ranged fiber laser welders. you’ll see a lot of variety from $20,000 to $100,000 in this price range. mid range machines range from high quality handheld laser welders to automatic cnc laser welders with 2 3kw lasers. a mid level welding machine is best suited to factories that perform welding operations daily. The laser welding (lw) or laser beam welding (lwb) process uses a highly concentrated beam of light energy to form weld and join metals or thermoplastics. as a powerful and focused laser beam is used, the electrons in the area get excited to a point where the material melts due to the atoms breaking the bonds with each other. by using a. Laser welding explained. laser welding uses a high precision laser beam to fuse metals and thermoplastics. the accuracy and precision of the process produces low thermal distortion, making it perfect for welding sensitive materials. the process is most often automated, allowing for high welding rates. let’s dive deeper into the concept behind.

Comments are closed.