Why Each Phase Of The Blow In Installation Process Is Essential Spanish

Why Each Phase Of The Blow In Installation Process Is Essenti Climate pro® insulation evolves as it moves from the bag to the hopper and through the hose. each phase in this installation process is essential to getting. Study with quizlet and memorize flashcards containing terms like what method is recommended for a weekly review of the tasks on your to do list? a. abc: action, blow off, or compromise b. three r: review, revise or recommend c. three d: delete it, do it now, or defer it d. none of these, reviewing your notes after you take them is unimportant a. true b. false, changing positions such as going.

The Blow Molding Process Explained 5 steps to effectively install blown fiber. 1. site survey & planning. the first crucial step in a blown fiber installation is conducting a thorough site survey. it involves assessing the route where the fiber will be installed, identifying potential obstacles, and planning the layout of micro ducts. during this phase, the team determines the. Google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other languages. The first phase will be the installation of 48 fibers, followed by 24 fibers in the second phase and a final 24 fibers in the third phase. we selected a 5 mile length for the comparison. background. blown fiber originated with british telecom in 1982, developed to permit switching between fiber types as they evolved. The fiber optic cable blowing process is often preferred for installations due to its numerous advantages over the pulling method. it minimizes damage to the cable, reduces the risk of jams in the conduit, and is faster, saving on manpower and resources. however, using a pulling eye and a winch may be more suitable in certain situations.

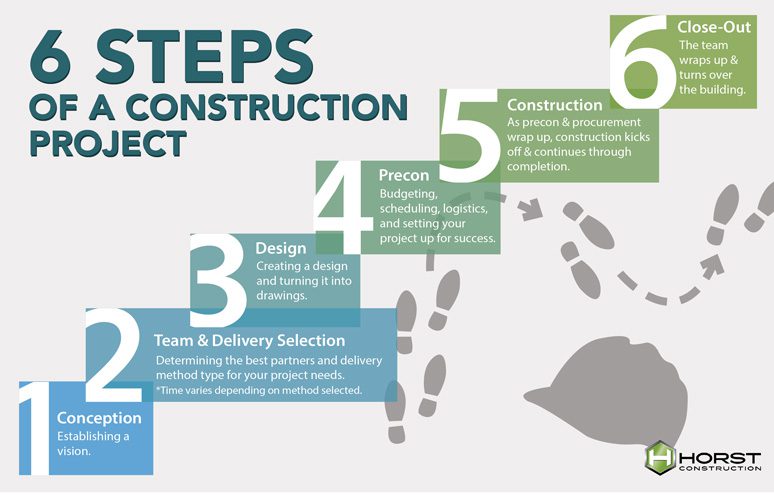

Project Phases Showing Basic Engineering Construction Vrogue Co The first phase will be the installation of 48 fibers, followed by 24 fibers in the second phase and a final 24 fibers in the third phase. we selected a 5 mile length for the comparison. background. blown fiber originated with british telecom in 1982, developed to permit switching between fiber types as they evolved. The fiber optic cable blowing process is often preferred for installations due to its numerous advantages over the pulling method. it minimizes damage to the cable, reduces the risk of jams in the conduit, and is faster, saving on manpower and resources. however, using a pulling eye and a winch may be more suitable in certain situations. Strip the cable jacket and cut back all fibers to the end of the jacket, leaving the aramid strength members only. separate the aramid yarn into two bundles and loop it through the swivel eve in opposite directions. tie knots in each bunch at the eye and loop the strength members back to the cable jacket. Using a measuring tape, measure the length and width of your attic space in feet. make sure to measure from wall to wall and from one end of the attic to the other. step 2: multiply length and width to get total area. multiply the length and width measurements together to get the total area in square feet.

Why Each Phase Of The Blow In Installation Process Is Essenti Strip the cable jacket and cut back all fibers to the end of the jacket, leaving the aramid strength members only. separate the aramid yarn into two bundles and loop it through the swivel eve in opposite directions. tie knots in each bunch at the eye and loop the strength members back to the cable jacket. Using a measuring tape, measure the length and width of your attic space in feet. make sure to measure from wall to wall and from one end of the attic to the other. step 2: multiply length and width to get total area. multiply the length and width measurements together to get the total area in square feet.

Comments are closed.