Wind Turbine Blade Repair Gurit

Wind Turbine Blade Repair Gurit Product overview. gurit offers a range of blade repair products that help to extend the service life of wind turbines, minimising turbine down times, easy to use while achieving consistent repair quality. the formulations have also been optimised for a wide range of temperature and humidity conditions, maximising the weather window for. The wind energy industry is one of gurit`s long standing, strategic target markets. gurit serves wind turbine blade manufacturers with a complete offering—from tooling (i.e. the design, production and supply of wind turbine blade moulds and related equipment), the development, production and supply of advanced composite materials to technical support and solutions for the repair of installed.

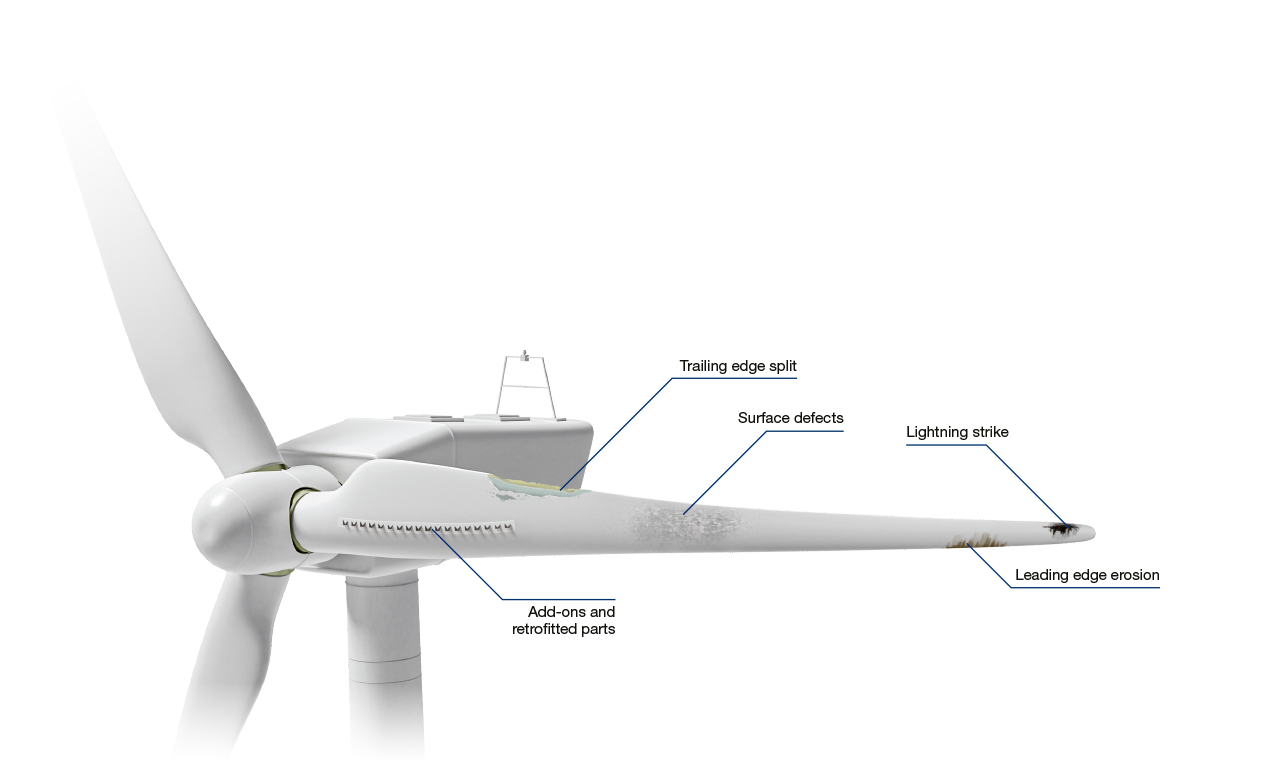

Wind Turbine Blade Repair Faqs Get Answers Now Renuvo™ is a uv curing resin system for the repair of wind turbine blades. it has been developed by gurit and thanks to its excellent properties the downtime. Tation and wind gusts, any hidden manufacturing flaws may also start to show up in the form of cracks in the blade surface, inside the laminates, or between the blade components. keeping blades in good condition is vital to the ability of the turbine to generate its designed power. even rela gurit’s new blade repair system uses. Keeping blades in good condition is vital to the ability of the turbine to generate its designed power. even relatively small amounts of leading edge erosion can affect the aerodynamic profile of the blade, leading to a performance drop of 3 4 percent and consequent loss of revenue. if erosion of leading edges is left unrepaired, then moisture. Renuvo™ pp uv curing prepreg system is a breakthrough uv curing prepreg system, developed by gurit as a repair system for wind turbine blades. it has been tested and proven to: enabling up tower repairs within one day. prepreg stacks of up to 6 layers (customised for individual repairs) are possible in one laminating operation.

Wind Turbine Blade Repair And Rotor Services Rope Partner Keeping blades in good condition is vital to the ability of the turbine to generate its designed power. even relatively small amounts of leading edge erosion can affect the aerodynamic profile of the blade, leading to a performance drop of 3 4 percent and consequent loss of revenue. if erosion of leading edges is left unrepaired, then moisture. Renuvo™ pp uv curing prepreg system is a breakthrough uv curing prepreg system, developed by gurit as a repair system for wind turbine blades. it has been tested and proven to: enabling up tower repairs within one day. prepreg stacks of up to 6 layers (customised for individual repairs) are possible in one laminating operation. A 5 mm thick laminate repair can be cured in 180 seconds. gurit lists the benefits of the blade repair system as: over 50% reduction in structural repair time; low odour, zero voc, resin; styrene and amine free; gl certification pending; extended weather window for repair from 5°c; zero post cure for repair; and. The wind turbine repair industry continues to grow at pace, due to the high number of existing wind turbines approaching an advanced age in their service life and therefore in need of more frequent maintenance. gurit, a leading supplier to the wind industry for over two decades, discusses its blade repair.

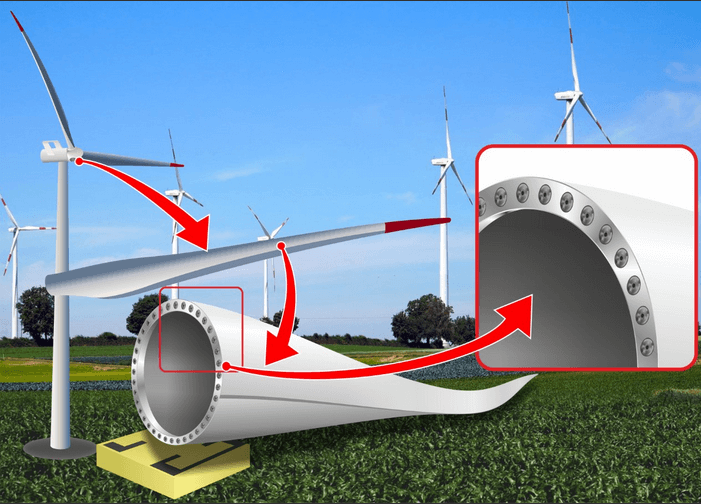

Denmarkтащs Cnc Onsite To Offer Onsite юааwindюаб юааturbineюаб юааbladeюаб Root Repairs A 5 mm thick laminate repair can be cured in 180 seconds. gurit lists the benefits of the blade repair system as: over 50% reduction in structural repair time; low odour, zero voc, resin; styrene and amine free; gl certification pending; extended weather window for repair from 5°c; zero post cure for repair; and. The wind turbine repair industry continues to grow at pace, due to the high number of existing wind turbines approaching an advanced age in their service life and therefore in need of more frequent maintenance. gurit, a leading supplier to the wind industry for over two decades, discusses its blade repair.

What Technologies Are Required To Repair Wind Turbine Blades

Comments are closed.