Working Of A Centrifugal Pump Engineering Learner

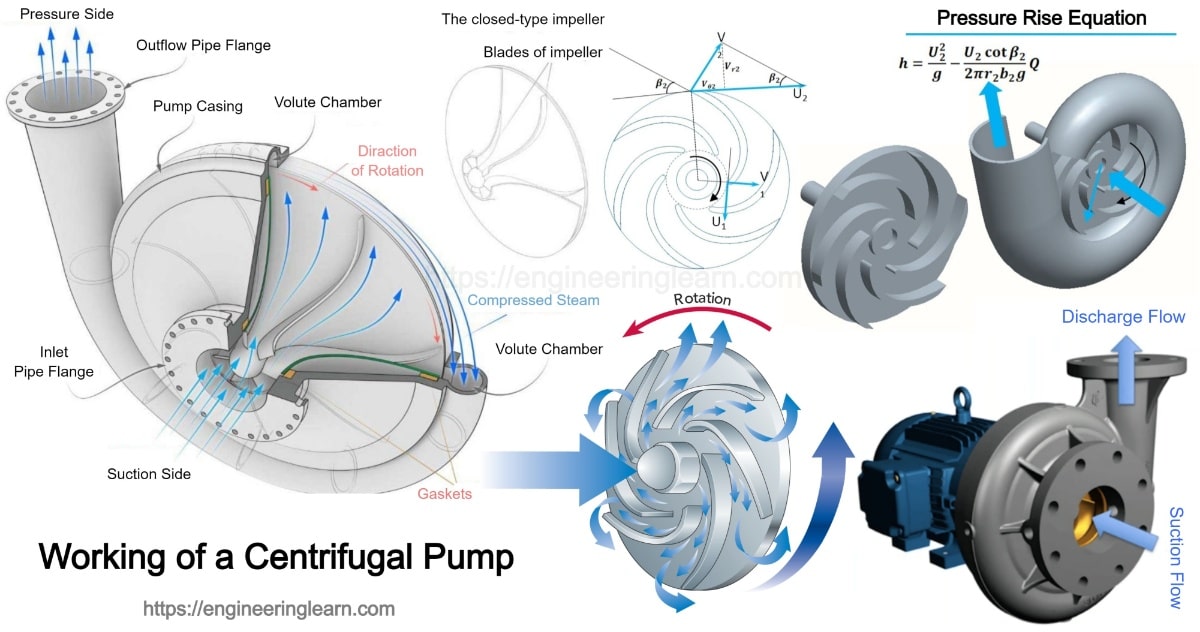

Working Of A Centrifugal Pump Engineering Learner Working principle of centrifugal pump. the general requirement of a pump is to transport liquids from low pressure regions to high pressure regions. the induction motor provides electrical energy and rotates the shaft, which causes the rotation of the impeller. when the impeller rotates, a region of low pressure is generated and water is then. The centrifugal pump defines as a hydraulic machine that converts mechanical energy into hydraulic energy by means of a centrifugal force acting on the fluid. in this, the pump uses a centrifugal force acting on the fluid surface to convert the mechanical energy. the centrifugal pump flows in a radially outward direction.

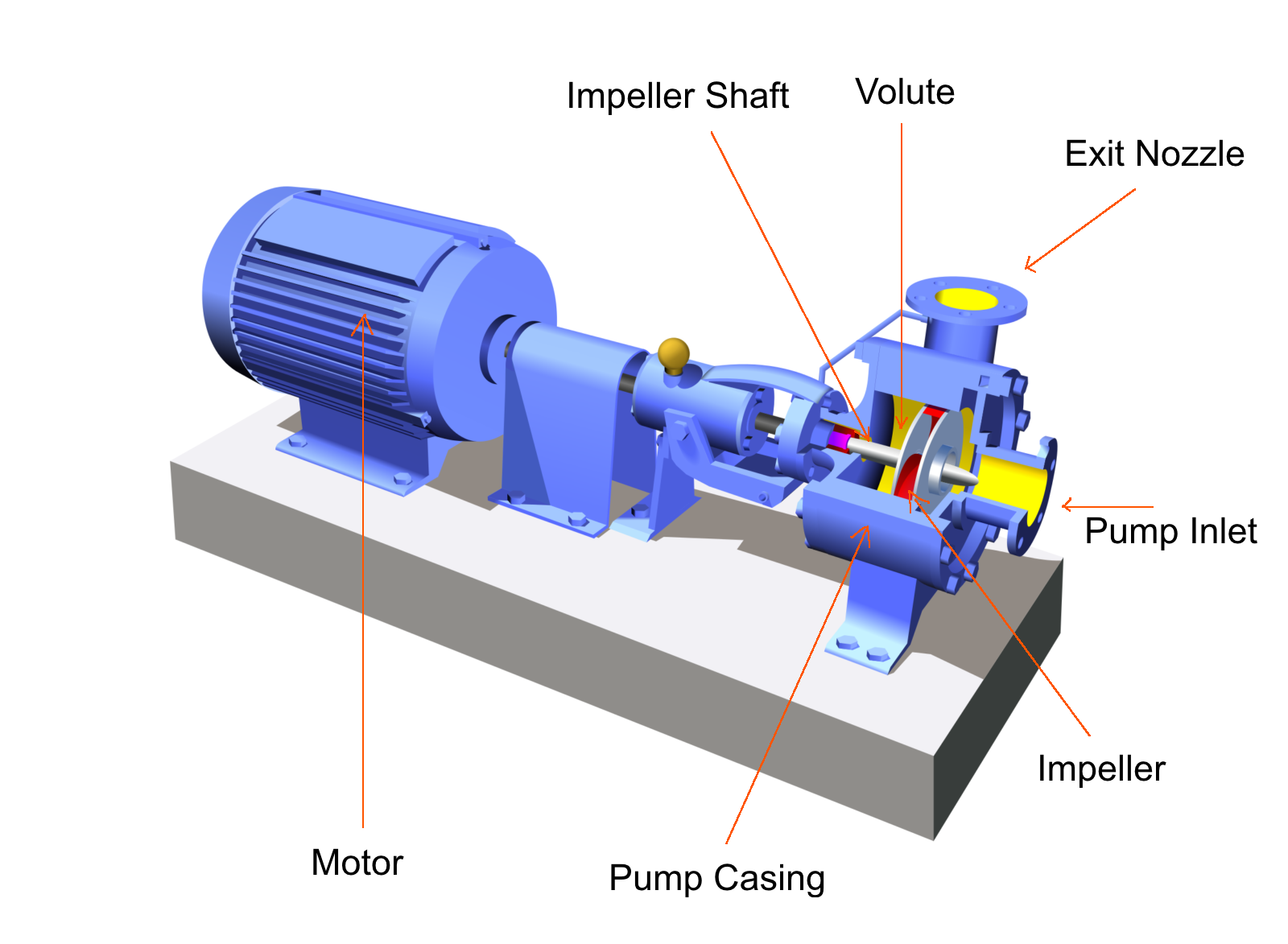

Centrifugal Pump Working Principle Main Parts With Application The centrifugal pump has two ports, an inlet, and also an outlet. the inlet is always through the centre, usually on a horizontal axis, as is refereed to as the suction line. whereas the exit is on the vertical axis and this is known as the discharge line. the impeller should always be submerged in water, otherwise it will not be able to draw. The impeller imparts centrifugal force onto the fluid which enables us to move liquids such as water through a pipe. the impeller is enclosed within the pump casing. the casing contains and directs the flow of water as the impeller pulls it in and pushes it out. therefore we have a suction in that and a discharge outlet. Fluid entering a centrifugal pump is immediately directed to the low pressure area at the center or eye of the impeller. as the impeller and blading rotate, they transfer momentum to incoming fluid. a transfer of momentum to the moving fluid increases the fluid's velocity. as the fluid's velocity increases its kinetic energy increases. The main parts of centrifugal pump are: 1. impeller. it is a wheel or rotor which is provided with a series of backward curved blades or vanes. it is mounded on the shaft which is coupled to an external source of energy which imparts the liquid energy to the impeller there by making it to rotate. fig 2: open, semi enclosed and enclosed impeller.

What Is A Centrifugal Pump The Engineer S Perspective Fluid entering a centrifugal pump is immediately directed to the low pressure area at the center or eye of the impeller. as the impeller and blading rotate, they transfer momentum to incoming fluid. a transfer of momentum to the moving fluid increases the fluid's velocity. as the fluid's velocity increases its kinetic energy increases. The main parts of centrifugal pump are: 1. impeller. it is a wheel or rotor which is provided with a series of backward curved blades or vanes. it is mounded on the shaft which is coupled to an external source of energy which imparts the liquid energy to the impeller there by making it to rotate. fig 2: open, semi enclosed and enclosed impeller. A centrifugal pump means a hydraulic machine that converts mechanical energy into hydraulic energy. a centrifugal pump is a rotary machine that converts mechanical energy or kinetic energy into pressure energy or pressure head by means of centrifugal force, is known as a centrifugal pump. in simple understanding,. A centrifugal pump is a piece of rotary equipment that converts kinetic energy into the pressure head of the liquid. external power from an electric motor or diesel generator drives the pump impeller. fluid enters the impeller, and by centrifugal force, it exits from the tip of the impeller. through volute casing, it discharges.

Comments are closed.