Working Of Double Acting Cylinder Of Pneumatic Circuit Using Pil

Pneumatic Circuits 1 Working Of Single Acting Cylinder Create the circuit diagram: using symbols for the double acting cylinder and the directional control valve, create a circuit diagram that shows the flow of air through the system. connect the input and output ports of the cylinder to the appropriate ports on the control valve. add other components: if there are other components in the circuit. The double acting pneumatic cylinder working principle involves using compressed air to create linear motion. it is a controlled application that involves a bidirectional force, extension and retraction. let’s have a look at the key stages of the double acting pneumatic cylinder working principle.

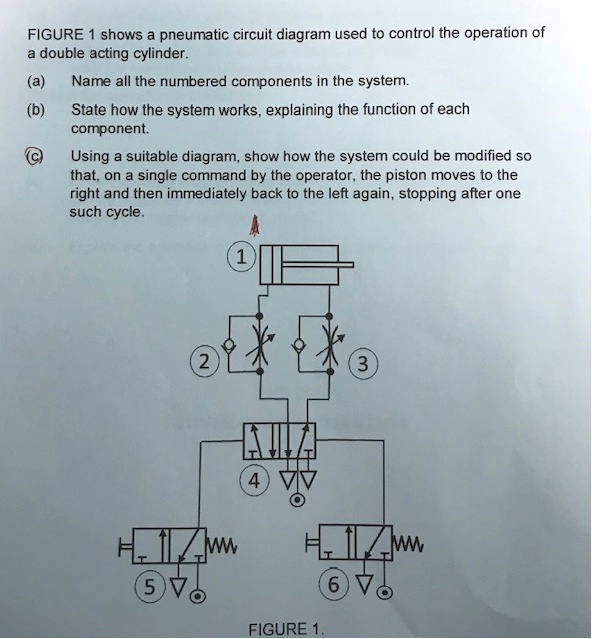

Solved Figure 1 Shows A Pneumatic Circuit Diagram Used To Control The Plc pneumatic circuit examples. example 1 : a double acting cylinder is used to perform machinng operation. pneumatic cylinder is advanced by pressing two push buttons simultaneously. if any one of the push button is released, cylinder comes back to start position. draw the pneumatic circuit, plc wiring diagram and ladder diagram to implement. Basic pneumatic circuits: white paper, pg. 6 white paper double acting cylinder circuit automation to extend and retract an air cylinder is common in many machines. figure 3 shows a pneumatic circuit consisting of a 4 way solenoid valve (sol01) operating a double acting cylinder (cyl01). filtered air from the air preparation unit. The following four pneumatic circuits can be used for air preparation, double acting cylinders, continuous cycling and hand control applications. they can also be subsystems in larger circuits. air preparation. before compressed air is used in a pneumatic device, it must be properly prepared so that it does not damage components. The diameter of the cylinder defines its force relative to the air pressure. the stroke tells us how many millimetres the piston and therefore the piston rod can travel. krämer kg, stammheimerstraße 10, d 70806 kornwestheim, germany, 0049 7154 178589 0, e mail: info@hafner pneumatik.de, web : hafner pneumatik .

Machine Drawing Double Acting Cylinder Pneumatic Circuit The following four pneumatic circuits can be used for air preparation, double acting cylinders, continuous cycling and hand control applications. they can also be subsystems in larger circuits. air preparation. before compressed air is used in a pneumatic device, it must be properly prepared so that it does not damage components. The diameter of the cylinder defines its force relative to the air pressure. the stroke tells us how many millimetres the piston and therefore the piston rod can travel. krämer kg, stammheimerstraße 10, d 70806 kornwestheim, germany, 0049 7154 178589 0, e mail: info@hafner pneumatik.de, web : hafner pneumatik . A double acting cylinder with a piston rod on both sides (fig.1.5) is a cylinder with a rod extending from both ends. this cylinder can be used in an application where work can be done by both ends of the cylinder, thereby making the cylinder more productive. double rod cylinders can withstand higher side loads because they have an extra. The first pneumatic scheme contains the following devices: a double acting cylinder with cushioning (duacy 1), two throttle valves, 4 2 way valve type, an air filter and the compressed air supply.

Pneumatic Control Valves Dt Online A double acting cylinder with a piston rod on both sides (fig.1.5) is a cylinder with a rod extending from both ends. this cylinder can be used in an application where work can be done by both ends of the cylinder, thereby making the cylinder more productive. double rod cylinders can withstand higher side loads because they have an extra. The first pneumatic scheme contains the following devices: a double acting cylinder with cushioning (duacy 1), two throttle valves, 4 2 way valve type, an air filter and the compressed air supply.

Pneumatic Circuit Diagram For Single Acting Cylinder

Comments are closed.